In the contemporary jewelry manufacturing industry, the surface treatment process not only determines the appearance and texture of the product, but also its durability, user experience and brand reputation. For this reason, the choice of surface treatment method has become a crucial link in jewelry manufacturing.

PVD coating (physical vapor deposition) is a high-end surface treatment process that has emerged in recent years and is widely used in stainless steel products, electronic products and high-end tools. It is regarded as a symbol of advanced technology by many designers and manufacturers for its high hardness, wear resistance, color stability and other characteristics. But at the same time, traditional electroplating technology, especially in silver and brass jewelry, is still widely used in the industry. What kind of selection logic is hidden behind this?

When buying jewelry, many consumers often see the terms “PVD coating”, “no fading”, “anti-scratch” and so on mentioned in the publicity, and mistakenly think that PVD is an “upgraded electroplating” applicable to all metals. In fact, this is a misunderstanding. Especially on active metal materials such as silver and brass, PVD coating is not as applicable as imagined.

Fulcol, a professional custom jewelry manufacturers, will take you to understand the essential difference between PVD coating and traditional electroplating, and analyze why PVD is not the best choice for silver and brass jewelry in combination with the specific process flow in jewelry manufacturing. At the same time, we will also introduce how to choose the most suitable surface treatment method in actual manufacturing to obtain more durable and beautiful jewelry quality.

Table of contents

- What is PVD coating?

- What is traditional electroplating?

- Why is it not recommended to use PVD coating on silver and brass jewelry?

- Analysis of actual problems of PVD coating on silver and brass

- Electroplating is still the preferred solution for silver and brass jewelry

- How to choose the right surface treatment for your silver or brass jewelry?

- Fulcol’s professional process advantages in the surface treatment of silver and brass jewelry

What is PVD coating?

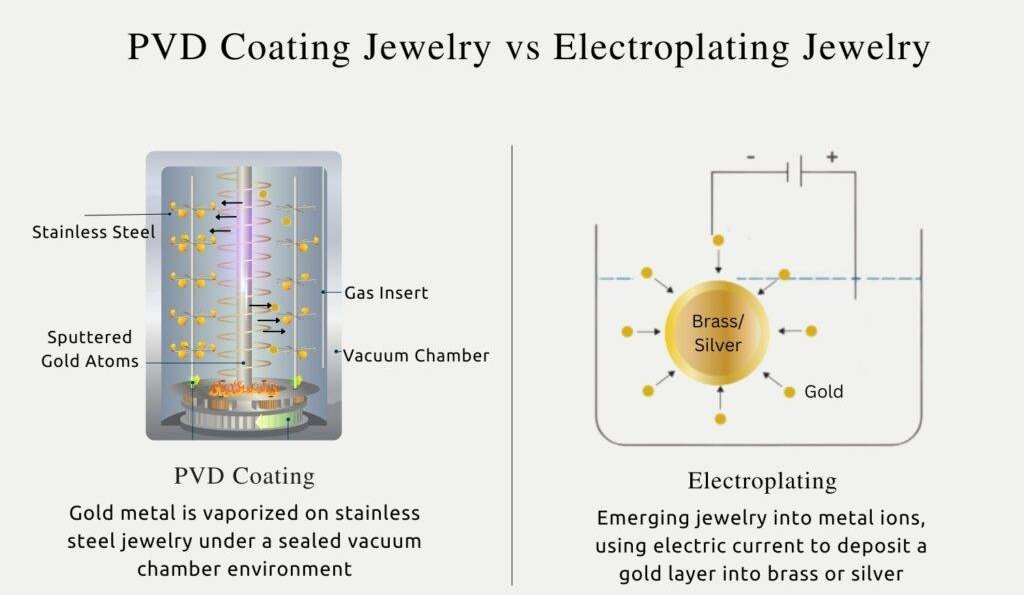

The full name of PVD coating is Physical Vapor Deposition, which means “physical vapor deposition” in Chinese. It is a technology that evaporates or sputters metal materials into gas and then deposits them on the surface of the workpiece under a vacuum environment. Its deposited layer is dense, hard and colorful. It is a dry coating process, which is different from traditional wet electroplating.

PVD coating process is mainly divided into three types:

Evaporation Coating: The metal is evaporated by heating, and the gaseous metal condenses into a film on the surface of the workpiece.

Sputtering Coating: The metal target is bombarded with plasma to splash metal atoms onto the surface of the workpiece.

Ion Plating: Combined with ionization treatment, it improves adhesion.

The advantages of PVD coating mainly include:

- High hardness and wear resistance: The hardness of PVD coating can reach more than 2000HV, which is much higher than traditional electroplating layer.

- Excellent corrosion resistance: The PVD film layer is dense and can effectively isolate air and moisture.

- Diverse and durable colors: It can form decorative layers that are not easy to fade, such as gold, black, rose gold, coffee, blue, etc.

- Environmentally friendly process: It does not use harmful substances such as cyanide and strong acid, and complies with RoHS environmental regulations.

Common application areas of PVD coating:

- Stainless steel watches, rings, bracelets

- High-end kitchen utensils and knives (such as black titanium coated knives)

- Medical equipment and automotive parts

- Mobile phone frames and high-end electronic product shells

However, it should be noted that PVD has extremely high performance requirements for the treated materials, which must have the characteristics of high temperature resistance, non-oxidation, and stable surface structure. This is also the fundamental reason why PVD cannot be easily applied to silver and brass.

What is traditional electroplating?

Electroplating is a process that uses the principle of electrolysis to deposit a thin layer of metal or alloy on the surface of a conductive material to enhance its aesthetics, corrosion resistance and functionality.

The basic process of electroplating is as follows:

Surface treatment: cleaning, degreasing, rust removal, pickling, activation treatment to make the metal surface clean and have good bonding.

Bottom layer electroplating: copper plating can fill micropores and provide good conductivity and bonding.

Main plating application: such as gold plating, silver plating, rhodium plating, etc., select electrolyte and voltage current density according to needs.

Sealing and passivation: coating a transparent protective layer to improve wear resistance and oxidation resistance.

Advantages of electroplating technology:

Strong applicability: a variety of active metals such as silver, copper, brass, zinc alloy, etc. can be electroplated.

Low temperature processing: the temperature of the electroplating process generally does not exceed 80°C, which will not affect the substrate structure.

High controllability: the thickness, color and gloss of the coating can be finely adjusted, which is suitable for highly customized products.

Moderate cost and high cost performance: especially suitable for mid-to-high-end and mass production.

In jewelry manufacturing, 925 silver jewelry is usually electroplated with platinum or rhodium to improve its gloss and anti-oxidation performance; while brass is commonly electroplated with 18K gold, rose gold, retro black gold, etc., giving it a luxurious appearance.

Why is it not recommended to use PVD coating on silver and brass jewelry?

Although PVD shines in some fields, it has many inadaptability when transplanted to silver and brass jewelry manufacturing, including:

High temperature destroys metal structure

The PVD process requires high temperature (generally 150~500℃) and vacuum environment. Silver is easily oxidized to form black silver sulfide at high temperature, while brass is brittle and loose in structure due to the volatilization of zinc elements. In this way, not only can the adhesion of the coating not be guaranteed, but the strength and beauty of the metal itself will be reduced.

PVD cannot compensate for microscopic defects

PVD is a “physical deposition” and has extremely high requirements for the surface finish of the substrate. It cannot fill the tiny depressions or oxidation points on the surface of silver and brass. On the contrary, the copper plating layer in traditional electroplating can be used as a “repairing layer” to improve the appearance of the finished product.

Easy to peel off and peel

Due to the physical and chemical structural changes of silver and brass during the PVD process, the film layer will partially fall off and peel, seriously affecting the life of the finished product and customer experience.

High cost and long cycle

PVD equipment has large investment, high operating costs, and limited processing volume per batch. For the large-scale production of conventional silver or brass jewelry, it is inefficient and has no cost advantage.

Appearance style limitation

PVD color tends to be matte metal, lacks the “warm luster” of traditional precious metals, and cannot meet the complex color and reflection requirements in jewelry design.

Analysis of actual problems of PVD coating on silver and brass

The following are some actual cases from the industry to illustrate the problems of PVD in the application of silver and brass:

Case 1: Silver ring becomes gray and peels off after PVD gold treatment

An e-commerce brand once tried to use PVD gold coating on 925 silver rings. As a result, it received a large number of customer complaints within 1 month: gray color, uneven discoloration, and after-sales return rate exceeded 35%. The reason is that the silver material oxidizes at high temperature and the coating cannot be fully attached.

Case 2: Brass pendant becomes brittle due to high temperature, causing cracking of finished products

A factory tried to use PVD technology to improve the surface hardness of brass pendants. As a result, the pendants became brittle and cracked due to thermal stress during processing, resulting in a large number of scrapped products and the customer terminated the cooperation.

These cases show that even if PVD itself is excellent, if the material matching is not considered, it may still lead to product failure and damage to the brand image.

Electroplating is still the preferred solution for silver and brass jewelry

Electroplating technology is widely used in silver and brass jewelry because of its strong adjustability, high durability and good color expression.

Specific advantages include:

- Low heat treatment temperature: no high temperature is required, and the silver and brass structures are not damaged

- Strong adhesion: electrolytic deposition can form a stable bond with the metal, which is wear-resistant and not easy to fade

- Customizable color: from platinum, gold, rose gold to black electroplating

- Partial plating repair: electroplating supports later repair and extends product life

Especially thickened electroplating (such as 0.1μm or more), which can greatly improve wear resistance while maintaining beauty.

How to choose the right surface treatment for your silver or brass jewelry?

Consumers and designers should evaluate the following dimensions when choosing a process:

Wearing frequency and scenarios: It is recommended to use thickened electroplating for daily wear; regular electroplating can be used for occasional use

Color requirements: If you need to achieve a specific color (such as vintage rose gold), it is recommended to choose traditional electroplating

Product budget and positioning: PVD is expensive and not suitable for batch silver jewelry

Brand process guarantee ability: It is particularly important to choose an experienced manufacturer with a quality control system

For example, Fulcol supports adjusting the thickness of the electroplating layer on demand to ensure that customers in different markets and different positioning can obtain ideal jewelry performance.

Fulcol’s professional process advantages in the surface treatment of silver and brass jewelry

As a custom jewelry manufacturer with many years of manufacturing experience, Fulcol has significant advantages in the surface treatment process of silver and brass jewelry:

Independent electroplating workshop, with multi-line gold plating, silver plating, and rhodium plating production lines

Thickened electroplating control technology, uniform and durable plating, stable color

Nickel-free environmentally friendly electroplating, REACH and RoHS compliant, suitable for high-end markets in Europe and the United States

Customized development support, supporting small batch proofing and exclusive color formula development

The factory team is familiar with the behavioral differences of different alloys and can match the most suitable process parameters according to customer product design needs. This is also one of the important reasons why Fulcol has won the trust of many brand customers.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

PVD coating does perform well in some areas, but this does not mean that it is suitable for all jewelry materials. As active metals, silver and brass have natural disadvantages in the face of high temperature and vacuum environment. Electroplating technology is still the most reliable surface treatment method for this type of jewelry due to its maturity and adaptability.

Understanding materials and processes is a basic skill that every jewelry brand, designer, and buyer must master. Instead of blindly pursuing “high-tech labels”, it is better to be down-to-earth and choose manufacturing processes that can truly stand the test of the market.

As a professional silver and brass jewelry manufacturer, Fulcol will continue to adhere to the concept of “scientifically matching materials and processes” to provide global customers with more high-quality, sustainable, durable and beautiful jewelry solutions.