Table of contents

What Is Jewellery Electroplating?

Jewellery electroplating is a process that deposits metal ions onto the surface of jewelry through electrolysis, creating a decorative and protective metal coating. This technique is widely used by custom jewelry manufacturers to enhance the appearance and durability of various pieces.

1. Main Functions of Electroplating

- Enhancing Visual Appeal:Electroplating with precious metals like gold, silver, and rhodium gives jewelry a luxurious color and mirror-like shine, making it more attractive.

- Improving Corrosion Resistance:The plating layer blocks air and moisture, effectively preventing oxidation and discoloration, thereby extending the jewelry’s lifespan.

- Enhancing Wearing Comfort:High-quality plating can isolate metals that may cause skin allergies (such as nickel), improving wearer comfort.

- Boosting Brand Value:Consistent and refined electroplating reflects the craftsmanship level of manufacturers, which is crucial for the competitiveness of custom jewelry manufacturers.

2. Common Electroplated Metals and Their Characteristics

| Gold (18K/24K) | Warm tone, strong oxidation resistance | High-end gifts, wedding jewelry |

| Silver | Bright and natural, good thermal conductivity | Daily wear, fashion jewelry |

| Rhodium | Excellent oxidation resistance, cooler tone | Silver protection, premium men’s jewelry |

| Rose Gold | Soft tone, trendy look | Couple’s jewelry, women’s styles |

3. The Role of Electroplating in Custom Jewellery

As a global hub for custom jewelry China, factories continuously optimize electroplating technology to meet the quality and environmental standards of different countries. The European market especially demands nickel-free plating, while North America emphasizes compliance with ROHS and REACH environmental regulations. Electroplating thus serves as a key link between design and market.

Detailed Electroplating Process for Custom Jewellery

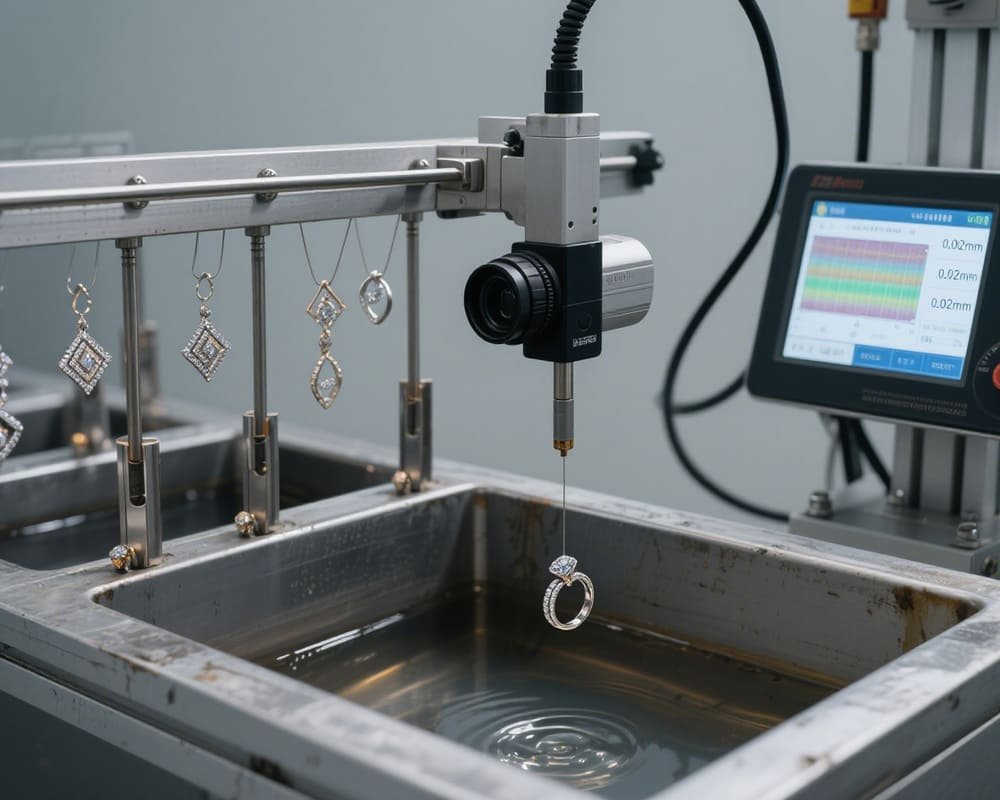

A complete electroplating process involves surface pretreatment, intermediate layer plating, main plating, and post-treatment. Each step determines the final quality.

1. Surface Pretreatment

- Degreasing and Cleaning:Use alkaline cleaners or ultrasonic cleaning machines to remove fingerprints, grease, and polishing residues.

- Acid Pickling:Apply diluted acids to remove oxidation layers and activate the metal surface.

- Electrolytic Activation:Use low-voltage electrolysis to further activate the surface and improve plating adhesion.

Insufficient pretreatment can cause bubbles, peeling, and uneven color in plating.

2. Intermediate Layer Plating

- Copper Plating:Enhances adhesion and surface smoothness; suitable for copper and stainless steel bases.

- Nickel Plating:Increases hardness and corrosion resistance; serves as a base for gold or silver plating.

Some clients choose nickel-free or rhodium-only plating due to allergy or environmental requirements.

3. Main Electroplating

- Gold Plating:Employ potassium gold cyanide or eco-friendly alternatives; control current density and temperature to achieve the desired tone.

- Silver Plating:Focus on electrolyte purity and brighteners to ensure a mirror finish.

- Rhodium Plating:Thin but very hard, protects silver jewelry from oxidation.

Choose hanging or barrel plating depending on product shape; barrel plating helps avoid dead spots on complex parts.

4. Post-treatment

- Pure Water Rinse:Multiple rinses to remove residual electrolyte and prevent surface stains.

- Drying:Use hot air or vacuum drying to avoid water spots.

- Polishing:Mechanical or manual polishing to enhance gloss.

- Sealing Treatment:Improve silver oxidation resistance and extend brightness.

- Thickness Inspection:Use XRF instruments to ensure plating uniformity and thickness, guaranteeing quality.

Fulcol’s Electroplating Advantages as a Custom Jewelry Manufacturer

As an experienced custom jewelry manufacturer, Fulcol boasts advanced equipment and mature process systems, specializing in meeting personalized requirements and high-quality standards.

1. Diverse Electroplating Technologies Supported

- Both traditional hanging and barrel plating

- Electroless plating and physical vapor deposition (PVD) for special effects

- Flexible selection based on design and structure

2. Environmentally Compliant Materials

- Electrolytes meet ROHS and REACH standards

- Nickel-free formulas ensure wearer safety

- Avoid export risks due to EU restricted substances

3. Strict Quality Control

- Real-time electrolyte concentration monitoring

- X-ray plating thickness testers ensure uniformity

- Salt spray tests validate corrosion resistance

- Full traceability of production records

4. Customized Services for Clients

- 3D modeling and sample color card support for accurate design reproduction

- Rapid prototyping for small-batch diverse orders

- International standard packaging and logistics coordination for global markets

These strengths make Fulcol a preferred choice among many European and American brands within custom jewelry China.

Practical Advice on Choosing the Right Electroplating

Selecting the appropriate plating affects not only appearance but also comfort and durability.

1. Color and Style Options

| Gold | Classic and luxurious | Weddings, gifts |

| Rose Gold | Soft and trendy | Couples’ jewelry |

| Silver | Simple and versatile | Daily wear |

| Black Rhodium | Bold and edgy | Men’s jewelry |

2. Plating Thickness Options

- Thin plating (<0.05μm): Suitable for fashion and affordable pieces; low durability.

- Standard thickness (0.08–0.15μm): Most brands use this balance of durability and cost.

- Thick plating (>0.2μm): Preferred for high-end and commemorative pieces; more wear-resistant.

3. Material Compatibility

- Copper and its alloys are compatible with various plating types.

- Zinc alloys require strong pretreatment to prevent peeling.

- Stainless steel is corrosion-resistant but harder to plate; thick plating or PVD recommended.

Common Electroplating Issues and Solutions

Typical plating problems and recommended fixes:

| Discoloration | Thin plating, poor protection | Thicken plating, apply sealants or rhodium layer |

| Bubbling/Peeling | Poor surface prep, excessive current | Improve cleaning, control current density |

| Uneven plating | Complex shape, uneven current | Use auxiliary anodes or barrel plating |

| Allergic reactions | Nickel release or layer damage | Use nickel-free processes and rhodium sealing |

Daily Care Tips

- Avoid contact with perfumes, chemicals, and sweat.

- Remove jewelry during swimming or exercise.

- Regularly wipe with soft cloth.

- Store in dry sealed bags.

Proper care extends plating life and maintains jewelry beauty.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

The electroplating process for custom jewellery bridges design and user experience. Accurate pretreatment, intermediate layers, main plating, and post-protection ensure jewelry shines beautifully and lasts longer. Leading custom jewelry manufacturers like Fulcol leverage diverse technologies, eco-friendly materials, and strict quality control to fulfill high-quality custom demands.

Whether you’re a startup brand or an established company, understanding plating details and choosing the right solutions is essential for market competitiveness and customer satisfaction.