Table of contents

What is PVD Coating? What is Traditional Electroplating?

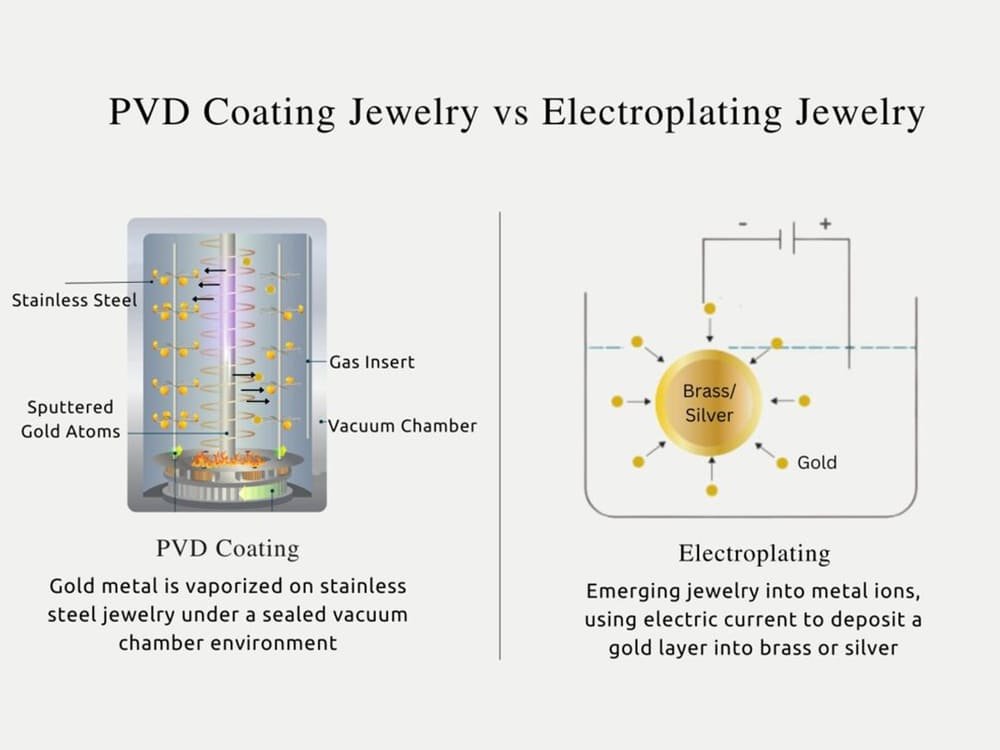

In the jewelry manufacturing industry, surface finishing techniques determine the final look and durability of a piece. The two most common methods are PVD Coating (Physical Vapor Deposition) and Traditional Electroplating. Both can enhance the beauty and longevity of jewelry, but their principles and applications differ greatly.

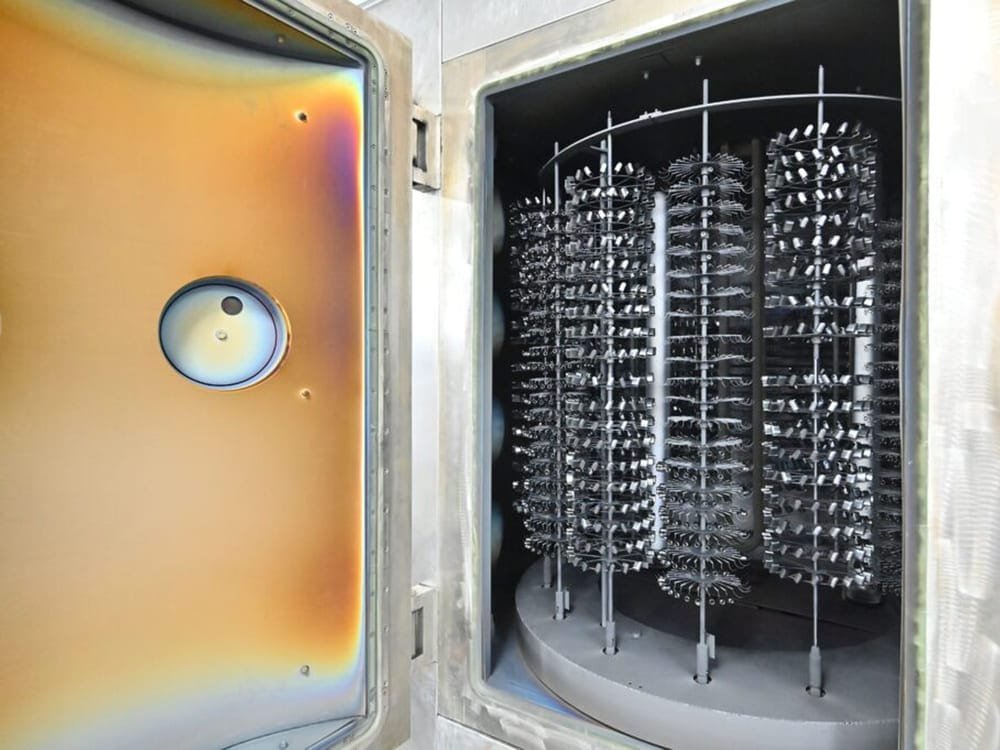

PVD Coating (Physical Vapor Deposition)

- Principle: In a high-temperature vacuum chamber, metals or compounds are evaporated into plasma particles and deposited onto the jewelry surface to form a dense coating.

- Common Colors: Black, gold, rose gold, gunmetal, etc., with a uniform metallic finish.

- Key Advantages: High hardness, scratch resistance, environmentally friendly, and long-lasting color.

- Applications: High-end watches, stainless steel jewelry, titanium accessories, electronic casings.

Traditional Electroplating

- Principle: Through an electrolytic process, metal ions are reduced and deposited on the jewelry’s surface, forming a stable metallic layer.

- Common Types: Gold plating, silver plating, rhodium plating, palladium plating, etc.

- Key Advantages: Mature technology, cost-efficient, natural luster, and compatible with a wide range of metals.

- Applications: Preventing silver tarnish (rhodium plating), gold-like appearance on brass (gold plating), luxury jewelry protection.

Why PVD Coating Is Not Suitable for Silver and Brass Jewelry

Although PVD technology performs exceptionally well on stainless steel and titanium, it is not an ideal choice for silver and brass. The reasons include:

- Material Compatibility Issues: Silver and brass are prone to reacting with oxygen or sulfur in the air. PVD coating cannot fully prevent oxidation, so tarnishing can still occur.

- Poor Adhesion: PVD adheres strongly to hard metals like stainless steel but poorly to softer metals like silver and brass, making the coating easy to peel off.

- Higher Cost: PVD requires expensive equipment and longer processing times, which is not cost-effective for silver and brass jewelry.

- Limited Industry Use: Most Brass Jewelry Manufacturers and Sterling Silver Factory still rely on electroplating rather than PVD—evidence of what the market truly trusts.

The Advantages of Electroplating in Silver and Brass Jewelry

Why do most factories still rely on electroplating? Because electroplating offers more practical benefits and value for silver and brass jewelry:

- Mature Technology: Electroplating has been in use for over a century, with proven stability.

- Aesthetic Appeal: Provides a natural and attractive luster that enhances jewelry design.

- Cost Efficiency: Requires less investment compared to PVD, making it ideal for large-scale production.

- Durability: Thick plating and rhodium plating significantly extend the life of silver and brass jewelry.

- Market Recognition: Customers are familiar with electroplating, and after-sales care is easier and more standardized.

Comparison Table: PVD vs Electroplating

| Aspect | PVD Coating | Electroplating |

|---|---|---|

| Principle | Metal vapor deposition in vacuum | Electrolytic metal deposition |

| Suitable Materials | Titanium, stainless steel | Silver, brass, copper, alloys |

| Adhesion | Poor on soft metals | Strong and reliable |

| Color Options | Limited, metallic tones | Wide variety (gold, silver, rhodium, etc.) |

| Cost | High, equipment-intensive | Lower, well-established |

| Industry Use | Niche, high-end stainless steel | Widely used in jewelry industry |

| Maintenance | Difficult to repair | Replating possible, flexible care |

This comparison makes it clear: for silver and brass jewelry, electroplating is the more cost-effective and reliable choice.

Fulcol’s Expertise in Surface Finishing for Silver and Brass Jewelry

As a custom jewelry manufacturer with years of experience, Fulcol has built significant expertise in surface finishing for silver and brass jewelry. The company stands out as a trusted partner for global brands, thanks to its advanced capabilities and strict quality standards.

- Independent Electroplating Workshop: Fulcol operates dedicated electroplating lines, including gold, silver, and rhodium plating, ensuring efficiency and quality consistency.

- Advanced Thick Plating Control: Through precise thickness monitoring, Fulcol ensures even, durable, and color-stable finishes that enhance both appearance and longevity.

- Nickel-Free Eco-Friendly Plating: All processes comply with REACH and RoHS standards, making Fulcol an ideal partner for brands targeting premium US and European markets.

- Custom Development Support: From small-batch sampling to exclusive plating formulas, Fulcol offers flexible custom solutions, helping brands create unique jewelry lines.

- Experienced Technical Team: Fulcol’s engineers understand the unique behaviors of different alloys and can fine-tune plating parameters based on customer designs, ensuring the best outcome. This technical strength is why Fulcol is trusted by leading Brass Jewelry Manufacturers and Sterling Silver Factory worldwide.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

For silver and brass jewelry, PVD Coating is not the ideal choice due to poor adhesion, higher cost, and limited compatibility. Electroplating, on the other hand, remains the mainstream solution with mature technology, better visual appeal, and lower production costs.

For brands, choosing an experienced partner is crucial. With expertise in plating thickness control, eco-friendly solutions, and custom development, Fulcol has become a preferred partner for global Brass Jewelry Manufacturers and Sterling Silver Factory.

Looking forward, electroplating will continue to play a key role in the silver and brass jewelry industry, and Fulcol will keep delivering trusted, high-quality surface finishing solutions.