Table of contents

- Understanding the Role of Rubber Molds in Jewelry Manufacturing

- Rubber Mold Production Steps for Custom Necklaces

- Fulcol’s Professional Advantages as a Custom Necklace Manufacturer

- The Process of Custom Sterling Silver Necklace Production

- Quality Control and Precision Assurance for Custom Sterling Silver Necklaces

Understanding the Role of Rubber Molds in Jewelry Manufacturing

In jewelry manufacturing, molds act as the bridge between design and finished products. Rubber molds, in particular, are widely used for producing custom necklaces due to their flexibility and high reproducibility. For a custom necklace manufacturer, rubber molds not only reduce costs but also ensure that complex designs can be produced consistently and accurately.

Compared with metal molds, rubber molds have several advantages:

- Flexibility: Suitable for intricate designs, capturing fine textures and structures.

- Cost efficiency: Faster production and lower investment, especially for small batches.

- High replication accuracy: Can be reused multiple times, ensuring consistent quality.

In the production of sterling silver custom jewelry, rubber molds play an irreplaceable role. They allow designers’ creativity to be quickly transformed into mass-producible pieces, satisfying personalization while ensuring commercial feasibility.

Rubber Mold Production Steps for Custom Necklaces

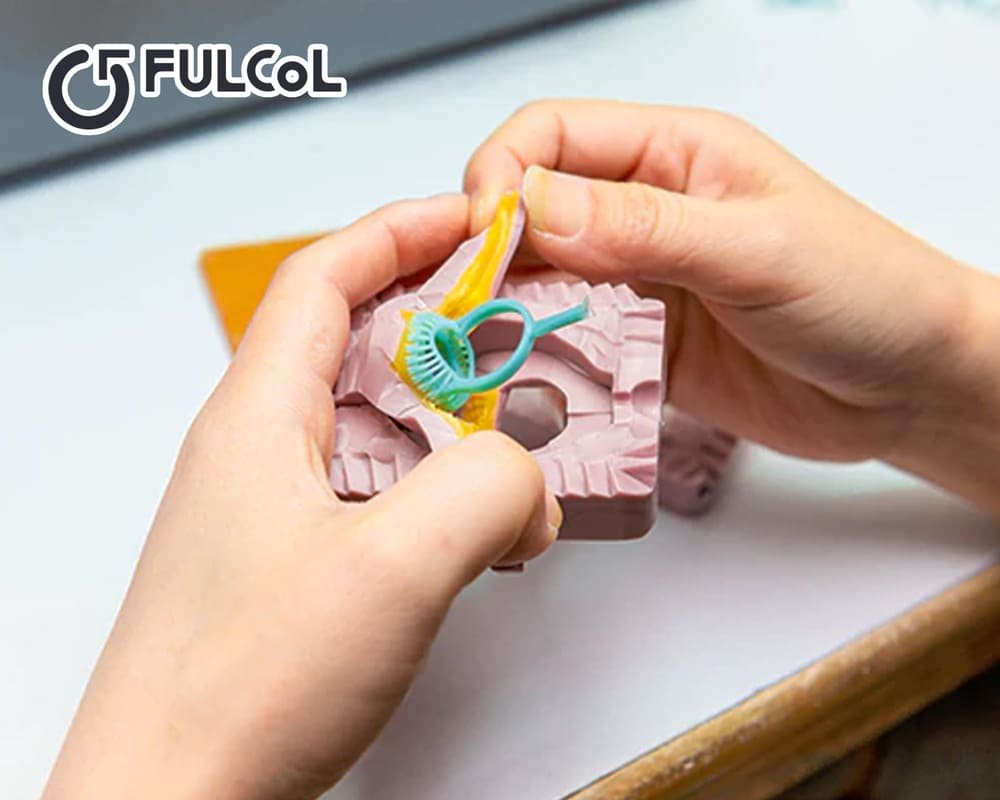

Creating a rubber mold is a craft that combines artistry and technology. The core steps are as follows:

- Material Selection

Commonly used rubbers include vulcanized rubber and silicone. Vulcanized rubber is wear-resistant and suitable for mass production, while silicone rubber is more flexible and captures intricate details better. - Production Process

- Wax carving: Make a wax model based on the design, which serves as the master model.

- Encapsulation: Place the wax model in a mold frame and pour rubber in layers.

- Curing: Apply heat and pressure to solidify the rubber around the wax.

- Mold opening: After cooling, cut open the mold to get the negative shape.

- Wax injection: Inject liquid wax into the mold to replicate the original design.

- Inspection: Check for bubbles, deformation, or cracks in the wax model.

- Common Issues and Solutions

- Bubbles: Pre-treat rubber in a vacuum chamber.

- Deformation: Maintain stable temperature and pressure.

- Shrinkage: Leave shrinkage allowance in the design.

These steps directly affect the quality of sterling silver custom jewelry, so each step must be strictly controlled.

Fulcol’s Professional Advantages as a Custom Necklace Manufacturer

Fulcol is a professional sustainable jewelry factory in China, specializing in ODM, customization, and wholesale production of silver and brass jewelry, including necklaces, earrings, rings, and bracelets. With over 20 years of industry experience, Fulcol has become a trusted custom necklace manufacturer globally.

- Sustainability and Responsibility

Fulcol uses eco-friendly materials and processes, meeting market demand while considering long-term environmental impact. - Advanced Equipment and Craftsmanship

Equipped with modern molding and precision machinery, combined with an experienced artisan team, Fulcol ensures that every detail of sterling silver custom jewelry is perfectly reproduced. - Flexible Minimum Order Quantity

Fulcol supports both startups and large-scale retailers with flexible MOQs, helping clients reduce inventory pressure and quickly respond to market demand. - Over 20 Years of Industry Experience

Fulcol not only manufactures products but also provides original designs, reliable production, and on-time delivery, supporting brand growth. - Customer Value and Brand Support

Fulcol integrates creative support with high-quality manufacturing, ensuring every piece of sterling silver custom jewelry balances artistic value and commercial viability.

The Process of Custom Sterling Silver Necklace Production

The complete production process of a custom sterling silver necklace includes the following stages:

- Design Stage: Communicate with the client to understand requirements and create a 3D CAD model, balancing aesthetics and manufacturability.

- Prototype Stage: Validate the design using wax models or 3D printing, and replicate with rubber molds for sample production.

- Casting Stage: Pour molten sterling silver into the mold to form the necklace, carefully controlling temperature and timing to prevent cracks or shrinkage.

- Surface Finishing: Polishing, grinding, and plating are performed to ensure smoothness and comfort, with optional gemstone setting if required.

- Quality Inspection and Delivery: Each piece undergoes dimensional checks, surface inspection, and comfort evaluation to meet international standards.

Through this process, Fulcol transforms client ideas into high-quality sterling silver custom jewelry that combines artistry with commercial value.

Quality Control and Precision Assurance for Custom Sterling Silver Necklaces

In jewelry manufacturing, mold precision determines the final product quality. Fulcol, as an experienced custom necklace manufacturer, has a comprehensive quality control system:

- Inspection Methods

- Dimensional checks using CNC measurement tools.

- Surface inspection under microscopes.

- Reproducibility tests to ensure consistency in large-scale production.

- Certification System

Fulcol follows ISO9001 and SGS standards to ensure standardized production processes. - Common Defects and Prevention

- Shrinkage: Allow for compensation in the design and control cooling.

- Cracks: Strictly control casting temperature and speed.

- Surface imperfections: Refined polishing ensures a flawless finish.

This end-to-end quality control ensures that Fulcol maintains a solid reputation in sterling silver custom jewelry production.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

The creation of sterling silver custom jewelry is both an art and a science, where rubber mold making is essential for precision, efficiency, and design flexibility. For brands seeking a reliable custom necklace manufacturer, Fulcol offers not only production but also sustainable practices, advanced technology, and over 20 years of experience.

As consumer demand for personalized and eco-friendly jewelry continues to grow, choosing the right partner is critical. Fulcol is committed to transforming creative ideas into high-quality jewelry, ensuring every necklace reflects both artistry and reliability.