Table of contents

Fulcol’s Brand History and Industry Position

As a leading custom earring manufacturer in Europe, Fulcol has been dedicated to the design and production of high-quality brass earrings since its establishment in 2004. With more than 20 years of manufacturing experience, Fulcol has developed into a comprehensive enterprise integrating design innovation, precision manufacturing, and international trade.

- Brand Development History: Fulcol initially focused on metal jewelry component processing and quickly gained the trust of international clients with exquisite craftsmanship and efficient service. As customization demand grew, the company gradually transformed into a full-solution manufacturer—covering concept design, sample development, mass production, and packaging—to form a complete production ecosystem.

- Industry Position and Advantages: Today, Fulcol has become a long-term partner of many European brands and designers, exporting products to Germany, France, Italy, and Nordic markets. With strict international standards and stable production capacity, Fulcol has taken a leading position in the brass earrings wholesale industry. The company’s annual export volume continues to grow, and it has gained customer trust through ISO9001 and multiple environmental certifications.

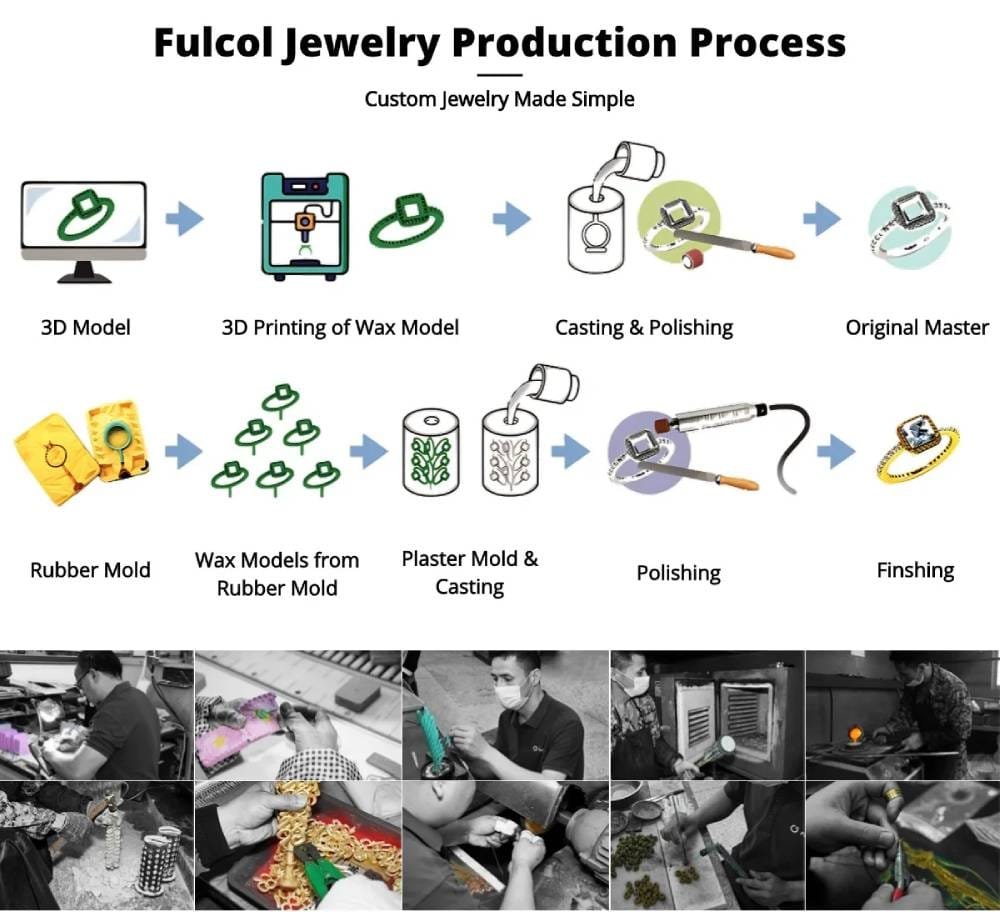

- Professional Team and Technical Strength: Fulcol owns an independent design team and a 3D modeling department capable of transforming client ideas into production-ready models. The factory is equipped with fully automatic polishing machines, vacuum electroplating lines, and nickel-free eco-friendly plating systems, ensuring that each product meets international standards in gloss, durability, and skin compatibility.

Design and Crafting Process of Custom Brass Earrings

Creative Design and Concept Development

The design phase is the core of Fulcol’s service system. The design team consists of 15 experienced jewelry designers familiar with market trends and wholesale client needs. The design process starts with brand positioning, target audience analysis, and budget discussions, followed by hand-drawn sketches or digital concept models.

During the digital stage, Fulcol uses CAD software such as Rhinoceros and MatrixGold for precise modeling, combined with 3D printing rapid prototyping, allowing clients to visualize the design within a short time.

Mold Making and Precision Processing

After the design is confirmed, Fulcol proceeds with mold making. Earring molds are made from high-precision aluminum or steel to ensure consistent size and clear details across batches.

The brass material is melted at high temperature and injected into molds to form the base shape of the earrings. To guarantee complex design accuracy, Fulcol applies CNC engraving, micro-carving, and laser cutting technology to refine details, ensuring precise texture, lines, and structure for every piece.

Surface Finishing and Plating Process

Fulcol provides various plating options such as silver and rose gold, using nickel-free plating to minimize allergy risks. Polishing involves micro-abrasive powder and ultrasonic cleaning for smooth and uniform surfaces. A transparent eco-protective coating is then applied to safeguard the plating and extend wearing durability.

Material Selection and Sustainability

Advantages and Features of Brass Material

Fulcol uses high-quality brass with a copper content of 60%–70%, offering ideal hardness, corrosion resistance, and processability—perfect for complex earring shapes and detailed engravings. Brass is not only durable and aesthetically pleasing but also provides excellent ductility and stability, ensuring long-term integrity with frequent wear.

Eco-friendly Plating and Nickel-Free Treatment

To ensure safe wear, Fulcol’s earrings feature nickel-free electroplating that complies with EU REACH standards. During production, an electrolyte recycling system minimizes wastewater discharge, supporting eco-friendly manufacturing.

Sustainable Sourcing

Fulcol sources brass from certified suppliers in Europe and the Middle East, all compliant with ISO 14001 environmental management standards. This ensures material traceability and aligns with global sustainability requirements.

Commitment to Health and the Environment

From materials to plating and packaging, Fulcol applies environmentally safe practices throughout production:

- Nickel-free and lead-free plating to prevent allergies

- Recyclable packaging materials to reduce environmental burden

- Energy-saving production techniques to support sustainability

This full-chain green approach has earned Fulcol high trust in the brass earrings wholesale market.

Advantages of Partnering with Fulcol

Collaborating with Fulcol provides brands not only with high-quality manufacturing support but also with a competitive edge in design and innovation.

- End-to-End Solutions: Fulcol delivers complete services—from concept, design, and prototyping to mass production—enabling clients to turn ideas into finished product lines easily.

- Low MOQ and Flexible Production: Understanding market challenges for new brands, Fulcol supports low minimum order quantities and agile scheduling, helping clients reduce inventory risks.

- High-Precision Craftsmanship and Consistency Control: Through a digital production monitoring system, Fulcol tracks process data at every stage, ensuring visual and dimensional consistency across batches.

- Brand Customization and Private Mold Services: Fulcol offers private mold design, logo engraving, and custom packaging to help brands build unique identities. Exclusive design files and mold protection guarantee market exclusivity.

- After-Sales and Quality Assurance: All products come with quality traceability and post-sale support. In case of plating defects, structure issues, or shipping damage, Fulcol provides prompt rework or replacements to ensure client satisfaction.

Frequently Asked Questions (FAQ)

(1) How to choose the right earring style and plating?

Choose based on brand identity and target audience. For luxury styles, geometric or pearl earrings are ideal; for younger markets, chain, layered, or asymmetric designs are popular. Gold and rose gold highlight warmth, while antique silver and gunmetal express individuality. Fulcol offers expert plating advice to match your brand aesthetics.

(2) What is the production time for custom brass earrings?

The average lead time is 25–35 days, depending on design complexity and plating type. With intelligent scheduling, Fulcol ensures on-time delivery, even offering rush production during seasonal peaks.

(3) Are Fulcol earrings hypoallergenic?

Yes. All earrings feature nickel-free hypoallergenic plating that meets EU REACH and ROHS standards. SGS-tested surfaces are smooth, skin-friendly, and maintain shine even after long wear.

(4) What finishing and packaging options are available?

Fulcol offers multiple finishes—bright gold, matte, antique silver, rose gold, and gunmetal—along with custom packaging such as branded boxes, labels, and hot-stamped logos to enhance retail presentation.

(5) How does Fulcol ensure product quality and after-sales service?

A confirmed sample is kept as the benchmark before production. During manufacturing, products undergo multiple checks for size, plating, and soldering strength. If any issue arises post-delivery, Fulcol provides repair, replacement, or reproduction options to ensure a worry-free experience.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

Fulcol is more than a manufacturer—it is a long-term strategic partner for jewelry brands. Whether you are an independent designer, e-commerce seller, or established jewelry company, Fulcol supports you with precise craftsmanship, flexible service, and genuine collaboration to create unique brass earring collections.

In an era valuing both individuality and quality, Fulcol stands out as a professional, reliable, and innovative custom earring manufacturer, providing trusted brass earrings wholesale solutions for brands worldwide.