Table of contents

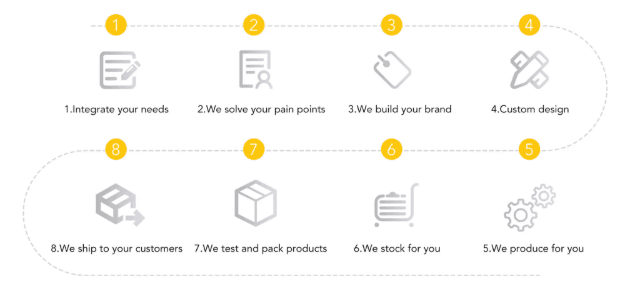

From Concept to Production: Necklace Design Process

Clarifying Design Requirements

- Before customizing a necklace, it is essential to clarify the design objectives, including style (such as minimalist, luxurious, or vintage), material (brass, 925 silver), budget, and target market.

- Different materials affect cost and wearing experience. For example, brass is suitable for large-scale production, cost-effective, and can be plated in various colors; 925 silver is more high-end, ideal for premium or collectible pieces.

- Clarifying these basic parameters provides guidance for subsequent design, material procurement, and production planning.

Concept Sketches and Digital Design Tools

- Initial concepts can be presented through hand-drawn sketches, but modern design relies more on digital tools such as Rhino, MatrixGold, and ZBrush.

- These software solutions transform 2D designs into 3D models, enabling detailed engraving, texture effects, and structural analysis.

- Digital rendering also visually demonstrates metal finish, plating colors, and gemstone settings, giving clients a realistic preview of the final necklace.

Structural Design and Manufacturability Assessment

- Design must not only be aesthetic but also manufacturable. Designers need to consider chain thickness, clasp strength, gemstone setting space, and overall balance.

- Unreasonable designs can increase casting difficulty or cause finished products to be fragile. Early assessment allows structural optimization at the design stage, reducing rework later.

3D Modeling and Rendering

- After conceptual design, 3D modeling creates precise models to ensure dimensions, proportions, and weight meet requirements.

- Rendering can simulate different materials, plating options, and lighting effects, helping clients confirm the final appearance before production and minimizing revisions.

Design Confirmation and Specification Documentation

- Before formal production, the design team produces detailed specifications, including dimensions, weight, plating thickness, gemstone types, and setting methods.

- These documents serve as technical references for production and are critical for communication with a custom necklace manufacturer / Custom necklace factory.

- Professional manufacturers also provide design optimization advice to ensure the design is both beautiful and manufacturable, improving production efficiency.

Fulcol’s OEM/ODM Customization Services

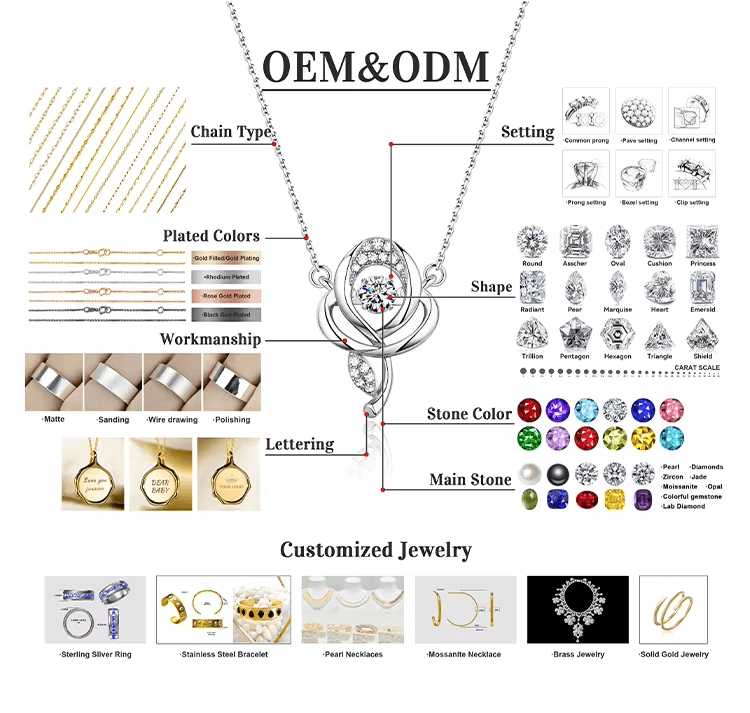

Material Customization

- Clients can choose brass or 925 silver as the main material for the necklace, depending on market positioning and budget.

- Special requirements can customize alloy composition or purity to meet luxury, high-end, or durability standards.

- Fulcol provides material traceability reports to ensure the quality and safety of each custom necklace.

Chain and Pendant Design Customization

- Chain Types: Snake chain, box chain, twisted chain, multi-layer chain, etc., customizable in length, thickness, and structure according to client design concepts.

- Pendant Shapes: Round, square, irregular, or brand logo, supporting embossing, hollowing, or engraving.

- Clasp and Chain Ends: Magnetic clasps, spring clasps, or special designs for comfortable and secure wearing.

Surface Treatment and Plating Customization

- Plating Colors: Gold, rose gold, white gold, black plating, customizable according to brand style.

- Surface Finishes: High polish, matte, brushed, or textured for enhanced necklace feel and uniqueness.

- Plating Thickness: Adjustable per client requirements, typically 3–5 microns, ensuring wear resistance and long-term durability.

Gemstone and Setting Customization

- Gemstone Selection: Natural gemstones, crystals, zirconia, etc., customizable in color and size.

- Setting Methods: Prong, bezel, micro-pave, or combination settings, ensuring both beauty and durability.

- Gemstone Layout: Single pendant setting, multiple stone arrangements, or personalized pattern designs.

Logo and Brand Personalization

- Clients can engrave or laser-mark brand logos on pendants, clasps, or chains.

- Packaging customization is also supported, including gift boxes, labels, and instruction cards, enhancing brand recognition.

- Batch consistency is guaranteed to ensure every piece meets brand visual standards.

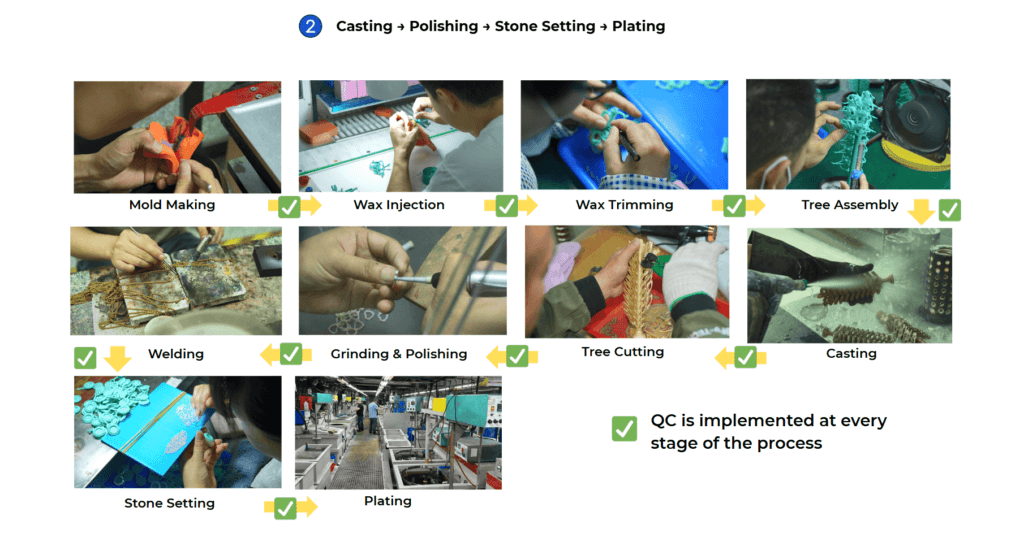

Complete Necklace Manufacturing Process

- Wax Model Production: The first step in customizing a necklace is creating a wax model for metal casting. Fulcol produces wax models by hand or via 3D printing according to client designs, ensuring complex textures and fine details are accurately reproduced. Wax model precision directly affects the final product detail and is the foundation of high-quality custom necklaces.

- Casting Process: Using lost-wax casting, the wax model is encased in refractory material, melted out, and molten brass or 925 silver is poured in. Fulcol adjusts temperature and timing according to material to ensure smooth metal flow and complete castings. After casting, debris removal and preliminary polishing prepare the piece for fine finishing.

- CNC Precision Machining:For complex pendants and specialized clasps, Fulcol uses CNC machines with precision up to 0.01mm, ensuring tight fit for chain links, clasps, and gemstone areas. This step guarantees structural reliability while preserving design aesthetics.

- Polishing and Surface Treatment: Each custom necklace undergoes multi-stage polishing, including coarse, medium, and fine polishing, for a smooth metal surface. Surface finishes such as high gloss, matte, brushed, or textured are applied according to client requirements, highlighting unique design. Polishing also provides a smooth foundation for plating and gemstone setting, ensuring uniform craftsmanship.

- Gemstone Setting: Based on client customization, prong, bezel, or micro-pave settings are performed, ensuring gemstones are secure and visually optimized. Layout strictly follows design specifications, reflecting creativity and brand style. Experienced setters handle intricate and micro-jewelry designs.

- Plating Process: Fulcol provides high-precision plating to achieve gold, rose gold, white gold, and other custom colors. Plating thickness is adjustable per client requirements, typically 3–5 microns, ensuring wear resistance and long-term durability. Corrosion and abrasion tests are performed to guarantee both beauty and functionality.

- Final Quality Check and PackagingEvery custom necklace undergoes strict inspection for dimensions, weight, plating thickness, and gemstone stability, ensuring alignment with design. Approved pieces are packaged according to client specifications, including gift boxes, labels, and instruction cards, reflecting brand personalization and premium quality.

Fulcol Factory Advantages and Efficient Customization

- Advanced Equipment and Production Capacity: Fulcol’s factory is equipped with modern production equipment, including 3D printers, CNC machines, plating lines, polishing stations, and laser engraving machines. These can handle complex designs, accurately reproducing client concepts, improving efficiency, and reducing human error.

- Extensive Customization Experience: With years of OEM/ODM experience, Fulcol understands design trends and quality standards in European, American, and Asian markets. Whether high-end 925 silver necklaces or personalized brass styles, the factory provides professional advice to optimize design and manufacturing processes, ensuring beauty and mass-producibility.

- Rapid Prototyping and Flexible Production: Fulcol offers rapid sample production, typically completed in 7–10 days for approval. Small-batch orders are scheduled flexibly, allowing clients to quickly transition from design confirmation to mass production. Efficient production management shortens lead times and improves market responsiveness.

- Strict Quality Control System:Fulcol has a comprehensive quality inspection process; each custom necklace is checked for dimensions, weight, plating, and gemstone security. Strict QC ensures each batch meets design and client expectations, enhancing brand credibility.

- Personalized Services and Brand Support: The factory supports personalization of pendants, chains, clasps, and packaging, including logo engraving, special finishes, and custom gift boxes. Fulcol integrates client branding into each product, enabling differentiated market positioning and stronger brand recognition.

Quality Control System in Jewelry Production

The quality control system is the core to ensuring high-quality necklaces. Fulcol implements strict inspection standards at every production stage:

- Raw Material Inspection: Brass composition, 925 silver purity, and impurity levels meet industry standards, ensuring stable metal performance.

- Dimension and Weight Checks: Precision measuring tools verify chain length, clasp size, and alignment with design specifications.

- Plating Adhesion Test: Salt spray and abrasion tests verify plating durability, preventing fading or peeling during daily wear.

- Gemstone Security Test: Ensures gemstones remain secure under normal use.

- Weld Strength Check: Chain links and clasp welds must withstand certain tension for safety.

- Final Manual Inspection and Packaging: Each necklace undergoes human re-checking to confirm appearance, plating, and packaging meet standards.

- Factory Certification: Fulcol holds ISO 9001 certification and follows eco-friendly plating standards, demonstrating professionalism and reliability.

This comprehensive QC system provides clients with reliable, high-quality custom necklaces while reducing after-sales risk.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

As a professional custom necklace manufacturer / Custom necklace factory, Fulcol demonstrates exceptional design capabilities, precision manufacturing, and efficient production management in OEM/ODM services. From concept, material selection, process treatment, to final inspection, every step reflects precise attention to client needs.

Whether small-batch sampling or large-scale customization, Fulcol provides flexible, high-quality, and personalized solutions, helping brands quickly turn ideas into market-ready products, enhancing brand competitiveness and customer satisfaction.