Table of contents

- Fulcol as a Custom Brass Jewelry Manufacturer Factory Strength

- Professional Brass Jewelry Factory Production Process and Key Equipment

- Fulcol Custom Design, Sampling, and Personalization Options

- Fulcol Focus on International Compliance and Quality Standards

- Fulcol Core Advantages as a Custom Brass Jewelry Manufacturer

Fulcol as a Custom Brass Jewelry Manufacturer Factory Strength

In the field of custom brass jewelry, a manufacturer’s factory strength directly determines product quality and project success. Fulcol, as a professional factory with 22 years of OEM/ODM custom jewelry manufacturing experience, has long focused on K gold, silver, and brass jewelry customization and wholesale production. The company has significant advantages in production system completeness, execution stability, and customization depth.

- Factory Direct Supply Model: Fulcol completes core manufacturing processes in its own factory, including mold development, casting, polishing, plating, and quality inspection, avoiding the quality fluctuations and delivery delays caused by multi-layer outsourcing.

- Extensive Experience Supporting Stable Delivery: With 22 years of manufacturing experience, Fulcol has a deep understanding of the structure, weight, wearing experience, and process limitations of various types of brass jewelry. This allows potential issues to be predicted during design and sampling, reducing risks.

- Flexibility and Scalability: Whether for small batch test orders or mass production, Fulcol ensures consistent craftsmanship while reasonably allocating production capacity to support clients’ smooth expansion.

- Technical R&D Capability: Fulcol has a professional R&D team and advanced design software to conduct innovative design, structural optimization, and new material exploration according to client needs, ensuring jewelry is both market-trendy and mass-production feasible.

- Customer Support and Assistance: Fulcol provides professional support from design communication and sample optimization to mass production, quickly responding to client needs, ensuring on-time delivery, and offering post-production technical guidance and problem-solving, making the client experience worry-free.

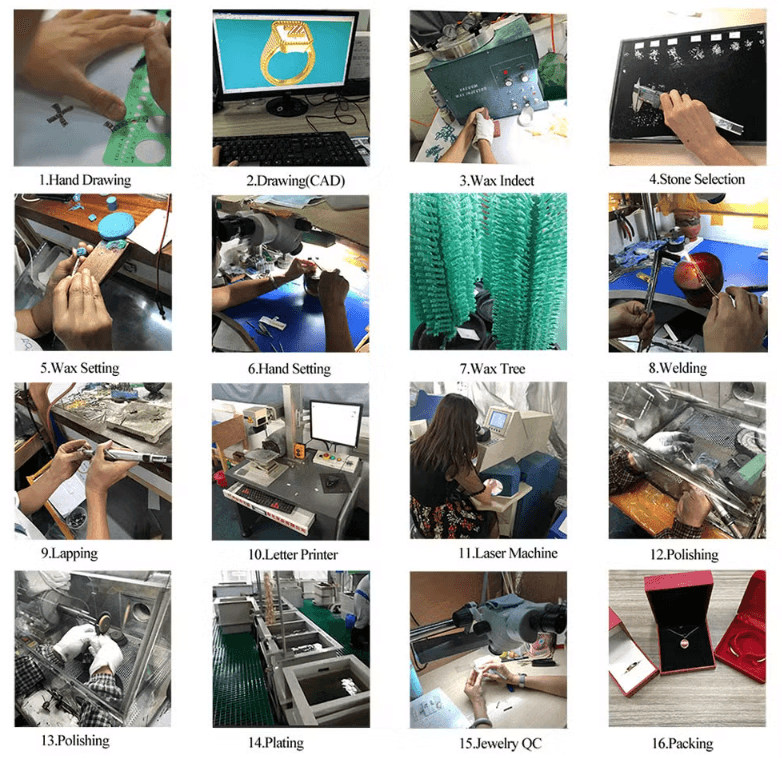

Professional Brass Jewelry Factory Production Process and Key Equipment

Standardized Production Process for Brass Jewelry

Fulcol follows a mature process for brass jewelry production, with strict control at every stage to ensure stable product quality:

- Design Confirmation and 3D Modeling: After receiving sketches or concepts from clients, the design team performs 3D modeling, optimizing proportions and structure to ensure comfort and mass production feasibility.

- Mold Development and Forming: Mold materials are selected according to the design, and size and detail adjustments are made to ensure casting precision and structural stability.

- Casting and Polishing: Precision casting equipment turns designs into physical jewelry, followed by polishing to achieve various surface effects, including mirror, high gloss, matte, and brushed finishes.

- Gemstone Setting (Optional): For designs requiring gemstones or decorative elements, precise installation is performed to ensure security, aesthetics, and safety.

- Plating Process: Plating is applied according to design requirements, including gold, silver, or rose gold, ensuring even color, strong adhesion, and durability.

- Quality Inspection and Packaging: Each piece undergoes visual, dimensional, and functional inspections and is packaged according to custom requirements to ensure safe transportation and brand presentation.

Key Equipment

Fulcol has a complete set of brass jewelry manufacturing equipment to ensure high precision, consistency, and mass-production capability:

- Precision casting machines: ensure dense metal structure and clear detail reproduction

- High-precision polishing machines: handle various surface finishes such as mirror, matte, and brushed

- CNC engraving machines: engrave logos, textures, and personalized patterns

- Plating equipment: multi-station plating lines supporting gold, silver, and rose gold

- Laser engraving/marking equipment: engraves brand markings on small parts like rings and bracelets

- Testing instruments: dimension measuring tools, plating adhesion testers, and salt spray test equipment

With both process and equipment safeguards, Fulcol maintains professional craftsmanship and stable quality across different jewelry types, batches, and customization requirements.

Fulcol Custom Design, Sampling, and Personalization Options

The core of custom brass jewelry is not just “whether it can be made,” but “whether the design is truly understood and feasible for mass production.” Fulcol not only handles production but also provides substantive support during design and sampling.

- Design Stage

Fulcol can perform professional 3D modeling and structural optimization based on client-provided sketches, reference images, or concept descriptions. The focus is not only on visual appeal but also on confirming size proportions, stress points, and production feasibility to prevent deformation, breakage, or discomfort during mass production. - Sampling Stage

Sampling is the most critical part of the customization process. Fulcol supports rapid sampling and allows adjustments within reasonable limits for size, structure, surface texture, and plating color. Full communication and optimization at this stage significantly reduce the cost and risk of modifications in bulk production. - Personalization Options

Fulcol provides highly flexible customization, including:- Material selection (primarily brass with various plating options)

- Size and structural customization

- Surface treatment (high polish, matte, brushed, etc.)

- Multiple plating and color options

- Logo engraving and brand identification

- Custom packaging and brand presentation

This capability, extending from the jewelry itself to brand presentation, makes Fulcol not just a manufacturer but a production partner supporting clients’ brand development.

Fulcol Focus on International Compliance and Quality Standards

In international markets, compliance of brass jewelry directly affects whether products can be sold smoothly. Different countries and regions have clear requirements on nickel release, heavy metal content, and plating environmental standards, which are key concerns for brands selecting suppliers.

Fulcol strictly follows international standards in material selection and production processes, offering nickel-free and lead-free plating solutions, and controls key risk points during production. All products undergo systematic quality inspections before shipment.

Inspection includes:

- Visual inspection of appearance and surface

- Dimensional and structural measurement

- Plating adhesion testing

- Color consistency check

- Component functionality testing

- Gemstone setting security check

- Salt spray testing (where applicable)

- Cleanliness and packaging integrity check

This multi-layered quality control system ensures high consistency in appearance, performance, and safety across different production batches, providing strong support for brands’ long-term market reputation.

Fulcol Core Advantages as a Custom Brass Jewelry Manufacturer

Fulcol’s core advantages lie not only in rich manufacturing experience but also in end-to-end capabilities from design to delivery, providing clients with reliable, high-quality custom solutions.

- Extensive Manufacturing Experience and Craftsmanship: With 22 years of OEM/ODM custom jewelry manufacturing experience, Fulcol is skilled in casting, polishing, plating, and gemstone setting for all types of brass jewelry, capable of handling complex designs and high-precision requirements. This experience allows the factory to evaluate design feasibility before production, preventing structural or process defects.

- Professional Design and R&D Capability: Fulcol has a professional design team capable of 3D modeling, structural optimization, trend analysis, and custom engraving. This team helps clients realize creative ideas while ensuring designs are feasible and durable for production. Clients can confirm proportions, structure, and details early, reducing costs of later modifications.

- Highly Flexible Customization: Whether material selection (brass, K gold, silver), surface treatment (high polish, matte, brushed), plating options, size, structure, logo engraving, or packaging, Fulcol offers highly customizable options. Low minimum order quantities allow emerging brands and small businesses to start their jewelry collections easily, with scalable production as business grows.

- Strict Quality Control System:Fulcol implements multi-level inspections, including appearance checks, dimension measurement, plating adhesion testing, color consistency, gemstone setting security, and salt spray tests, ensuring performance, appearance, and safety remain consistent across batches, safeguarding long-term market reputation.

- Adaptability to Brands and Wholesale Brass Jewelry Markets: Whether for clients seeking a Custom Brass Jewelry Manufacturer or wholesale brass jewelry, Fulcol can adjust production processes and delivery strategies according to client needs, balancing flexibility for small batches with stability for mass production, helping clients maintain competitiveness in different markets.

Through these advantages, Fulcol is not just a manufacturer but a trusted partner for global brands, providing full support from creative concepts to mass production of high-quality, unique brass jewelry.

| Start Your Custom Order | Email: info@fulcol.com | Number:+86-18876512305 |

Choosing the right Custom Brass Jewelry Manufacturer is fundamental to brand success. Leveraging 22 years of manufacturing experience, professional craftsmanship, flexible customization, and international quality standards, Fulcol provides reliable brass jewelry manufacturing solutions for global brands, wholesalers, and designers.

From concept to finished product, from small batches to scalable production, Fulcol consistently supports clients with stable quality and clear communication. If you are seeking a partner who understands both manufacturing and brand needs, Fulcol is a long-term, trustworthy choice.