Table of contents

Basics of Electroplating for Brass Jewelry

Brass jewelry is favored for its warm color, elegant texture, and affordable price, making it popular among designers and consumers. However, untreated brass is prone to oxidation and discoloration. Over time, it may darken or lose its shine, affecting both aesthetics and durability. Therefore, electroplating plays a crucial role in brass jewelry manufacturing.

Electroplating is a process that uses electrolysis to deposit a layer of metal on the surface of brass. This process not only gives jewelry the desired shine and color but also forms a protective layer to resist air, sweat, and daily friction. The main functions of electroplating include:

- Protection: The plating layer isolates oxygen and moisture, slowing brass oxidation and maintaining jewelry shine.

- Aesthetic Enhancement: Different plating metals provide a variety of colors, such as bright gold, rose gold, and silver, allowing diverse design possibilities.

- Durability Improvement: The thickness, metal choice, and process quality directly affect the lifespan of jewelry. Proper thickness and high-quality plating significantly reduce wear and fading.

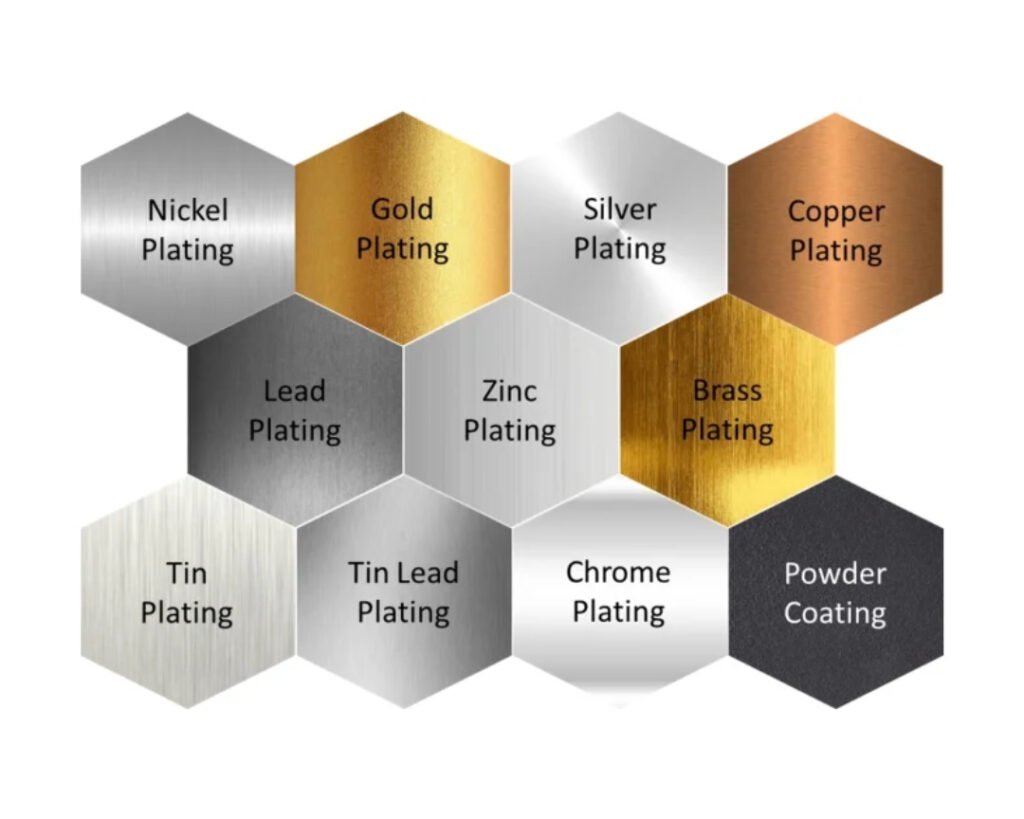

Common plating metals include gold, silver, rhodium, nickel, and PVD coatings. Each metal has unique characteristics. For example, gold plating enhances luxury, rhodium prevents allergies, and PVD provides rich colors and high wear resistance. For a professional brass jewelry manufacturer, selecting the right metal and thickness is essential to ensure product quality and customer satisfaction.

Different Electroplating Methods and Their Applications

Brass jewelry offers a variety of electroplating methods, each with distinct visual effects, durability, and costs. Common methods and their applications include:

1. Gold Plating

Gold plating is the most common method and can be divided into bright gold, matte gold, and high gold.

- Bright Gold: High surface gloss, suitable for bracelets, rings, and small jewelry pieces, instantly enhancing a luxury feel.

- Matte Gold: Soft luster, suitable for modern minimalist earrings or necklaces.

- High Gold: Thicker gold layer (5–10 μm) with excellent wear and corrosion resistance, ideal for long-term wearable rings and bracelets, making it a preferred choice for brass high gold jewellery manufacturers.

2. Silver Plating

Silver-toned jewelry is cool and elegant but easily tarnishes.

- Increasing thickness or applying anti-oxidation treatment improves durability.

- Suitable for bracelets, necklaces, and earrings, especially for low-key luxury designs.

3. PVD / Vacuum Coating

PVD (Physical Vapor Deposition) is an advanced plating process.

- Advantages: Environmentally friendly, wear-resistant, and rich in colors.

- Applications: High-end brass jewelry such as colorful bracelets and custom pieces. PVD achieves red, black, blue, and other effects while improving wear resistance.

4. Rhodium Plating

Rhodium provides a platinum-like shine and anti-allergic properties, often used for rings, earrings, and high-end necklaces.

- It corrects the yellowish hue of brass and enhances overall quality.

- Suitable for high-end jewelry and sensitive skin wearers.

By choosing the right electroplating method, brass high gold jewellery manufacturers can produce visually appealing, durable, and market-ready products tailored to jewelry type and design style.

Choosing the Right Plating Thickness and Materials

Plating thickness and materials are key factors determining brass jewelry quality. Thickness is measured in microns (μm); the thicker the layer, the better the wear and corrosion resistance, but the cost increases. Recommendations include:

- Thickness Standards and Lifespan

- Everyday jewelry (earrings, pendants): 0.5–2 μm is sufficient.

- Frequently worn jewelry (rings, bracelets): ≥3 μm; high gold can reach 5–10 μm.

- Differences by Jewelry Part

- Areas in contact with skin or inner sides wear faster and need thicker plating.

- Bracelet exteriors, subject to friction, also require moderate thickness.

- Material Selection

- Gold Plating: Offers luxury feel; high gold has best wear resistance.

- Rhodium Plating: Anti-allergic, suitable for direct skin contact.

- Silver Plating: Cool tone, requires anti-oxidation treatment.

- Common Issues and Solutions

- Fading: Increase thickness or select corrosion-resistant metal.

- Peeling: Optimize pre-treatment such as polishing and base plating.

- Color unevenness: Maintain stable current and solution concentration.

Scientific selection of thickness and materials allows a brass jewelry manufacturer to reduce fading and wear risks and enhance customer satisfaction.

Plating Thickness, Shine, and Durability

Electroplating not only decorates but also improves the durability and appearance of brass jewelry. Understanding the relationship between thickness, shine, and durability helps produce high-quality products.

- Thickness and Durability

- Greater thickness improves wear resistance.

- High gold plating ≥5 μm ensures long-term use of rings and bracelets without fading.

- Shine and Uniformity

- Shine depends on surface smoothness and reflectivity.

- Uniform plating prevents dark spots or color differences, ensuring overall aesthetics.

- Thickness Misconceptions

- Thicker is not always better; excessive thickness may cause edges to warp or affect design details.

- Proper thickness combined with high-quality metals and scientific processes balances durability and appearance.

- Evaluating Plating Quality

- Visual inspection: uniform shine, no spots or bubbles.

- Wear test: minimal fading after light friction.

- Professional tools: thickness gauge or microscope to check uniformity.

Understanding these relationships helps brass high gold jewellery manufacturers make scientific decisions during design and production, enhancing product quality and market competitiveness.

Five Reasons to Choose Fulcol’s Electroplating Services

- Rich Experience: Fulcol has years of experience in brass jewelry electroplating, covering bracelets, necklaces, rings, and earrings. Years of practice allow Fulcol to provide the best plating solutions for different designs and materials, ensuring each piece meets high standards of shine and durability.

- High-Quality Standards: Fulcol precisely controls plating thickness, performs wear tests, and checks surface shine to ensure stable product quality. Compliance with international environmental and safety standards (RoHS, ISO) guarantees jewelry is not only beautiful and durable but also globally market-compliant.

- Diverse Plating Options: Fulcol offers high gold, silver, rhodium, and PVD plating to meet a variety of styles and design requirements. Whether luxurious rings or colorful bracelets, the appropriate plating method can be selected.

- Personalized Customization: Fulcol can tailor plating solutions according to jewelry type and design requirements, covering color, shine, thickness, and surface texture to ensure products are both aesthetically pleasing and comfortable.

- Technical Support and After-Sales: Fulcol provides professional guidance to help clients correctly use and maintain plated jewelry. Its complete after-sales system ensures timely resolution of issues, extending the life of the jewelry.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

Choosing the right electroplating process is crucial for brass jewelry appearance, durability, and customer satisfaction. From gold and silver plating to PVD and rhodium, each method has unique advantages. Understanding the relationship between plating thickness, shine, and durability allows brass jewelry manufacturer and brass high gold jewellery manufacturers to produce high-quality, beautiful, and durable products. Partnering with Fulcol ensures optimal protection and presentation for brass jewelry, providing customers with long-lasting wearable experiences.