Table of contents

Electroplating and Thickness for Brass Jewelry

In modern jewelry design, brass jewelry is highly favored for its elegant luster and excellent malleability. However, brass itself is prone to oxidation and tarnishing, and prolonged wear may lead to discoloration and surface wear. Therefore, electroplating has become a key process to enhance the durability and appearance of brass jewelry. Electroplating not only gives jewelry different colors and textures but also effectively extends its lifespan.

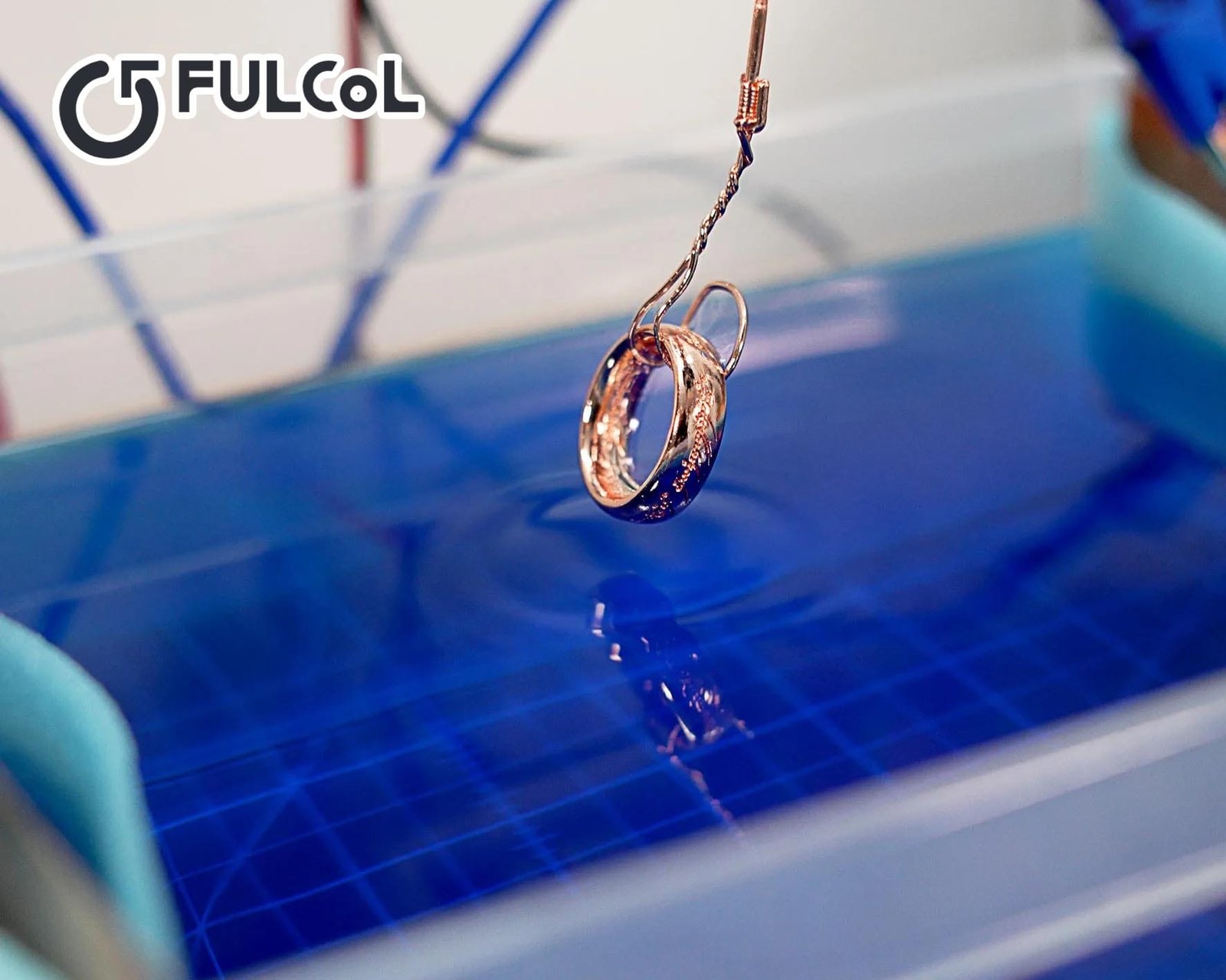

Electroplating Principles

Electroplating is the process of depositing metal ions onto the surface of brass through an electrochemical reaction to form a uniform metal layer. Common plating metals include:

- Gold Plating: Provides luxurious golden shine and good anti-oxidation performance

- Silver Plating: Shows bright silver color but is sensitive to air and sweat, requiring proper thickness

- Rhodium Plating: Often used for white jewelry, significantly increasing wear resistance and gloss

Electroplating Thickness Concept and Measurement

Plating thickness is usually measured in microns (µm). Thickness directly affects jewelry durability, gloss retention, and oxidation resistance. Thin plating is cost-effective but prone to wear, thick plating is more durable but may obscure fine details. Measurement tools such as XRF spectrometers ensure precise control of plating thickness to meet desired performance.

Impact of Thickness on Jewelry Performance

- Durability: Increased thickness significantly extends the lifespan, for example, 1 µm gold plating generally lasts 6–12 months, while 2 µm or more can last 2–3 years

- Appearance: Uniform thickness maintains consistent gloss, preventing uneven dulling or fading

- Anti-oxidation: The thicker the metal layer, the better the protection of the brass base, effectively preventing discoloration

Comparing Electroplating Thickness Levels

| Thickness Range | Advantages | Disadvantages | Suitable Applications | Expected Lifespan |

|---|---|---|---|---|

| Thin 0.1–0.5 µm | Low cost, suitable for display or short-term wear | Prone to wear, limited oxidation resistance | Display pieces, seasonal fashion jewelry, lightly worn earrings | 3–6 months |

| Medium 0.5–2 µm | Balance of durability and cost, suitable for daily wear | Slightly higher cost, design details preserved | Necklaces, bracelets, rings for daily wear | 6–24 months |

| Thick 2 µm+ | Best wear resistance, strong anti-oxidation, long-lasting gloss | High cost, may cover fine carvings or textures | High-end jewelry, long-term wear, custom gifts | 2–3+ years |

Choosing the right plating thickness should balance durability, appearance, and cost according to the type of jewelry and usage needs.

How to Choose the Right Plating Thickness

Selecting the plating thickness for brass jewelry requires considering metal type, jewelry style, wearing environment, and budget to balance appearance, durability, and cost-effectiveness. The following four aspects provide practical guidance:

1. Recommended Thickness for Different Plating Metals

- Gold Plating: Usually 0.5–2 µm, suitable for rings, bracelets, and necklaces. For high-end customization, 2 µm+ improves wear and oxidation resistance.

- Silver Plating: Recommended 0.5–1.5 µm, suitable for earrings and necklaces; combining with rhodium plating can extend lifespan.

- Rhodium Plating: 0.1–0.5 µm is sufficient to enhance gloss and wear resistance, mainly for white jewelry or protecting silver-plated pieces.

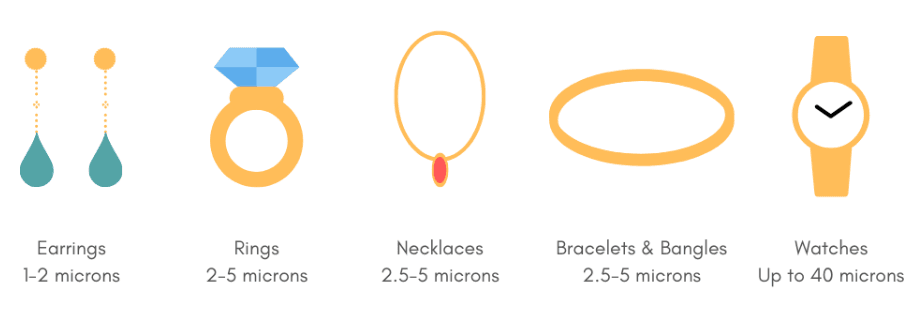

2. Suitable Thickness by Jewelry Type

- Rings: 1–2 µm recommended due to frequent contact with fingers.

- Bracelets: 1–2 µm, frequent friction, slightly higher thickness extends lifespan.

- Necklaces: 0.5–1.5 µm, less friction, maintaining appearance and gloss is sufficient.

- Earrings: 0.5–1 µm, close to skin, moderate thickness prevents fading and allergies.

3. Consider Wearing Frequency and Environment

- High-frequency wear (daily use, contact with water or cosmetics): Choose thicker plating for enhanced wear resistance and anti-oxidation.

- Low-frequency wear (occasional or collectible pieces): Thin plating is sufficient, cost-effective while maintaining shine.

- Humid or easily oxidizing environments: Prefer rhodium plating or thicker gold layers to extend jewelry lifespan.

4. Budget and Batch Production Balance

- For wholesale brass jewelry production, medium thickness (0.5–2 µm) is usually the best choice, balancing durability and cost-effectiveness.

- Use XRF spectrometers to ensure consistent thickness across each piece, improving production efficiency and reducing rework.

Fulcol’s Expert Solutions for Electroplating Thickness

- Experienced Professional Team: Fulcol has over 20 years of experience in brass jewelry manufacturing, familiar with K-gold, silver, and brass plating characteristics. The team combines design and production expertise to transform ideas into market-ready products, ensuring a balance between aesthetics and durability.

- Customized Electroplating Thickness Plans: Fulcol provides thickness recommendations from 0.1 µm to over 2 µm according to different metals and jewelry types (rings, bracelets, necklaces, earrings), optimizing gloss longevity, wear resistance, and anti-oxidation performance to meet diverse customer needs.

- Quality Control in Batch Production: For wholesale brass jewelry, Fulcol ensures thickness consistency through standardized processes and advanced equipment. XRF spectrometers is used to verify each batch meets the target thickness standard.

- End-to-End Customer Support: Fulcol offers full services from 3D modeling, rapid sample production to custom engraving, brand marking, and packaging. Flexible minimum order quantities and batch production balance help clients achieve the best combination of creativity and production efficiency.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

Choosing the right electroplating thickness is essential for ensuring the durability, appearance, and customer satisfaction of brass jewelry. By scientifically understanding plating principles, thickness measurement methods, and effects of different thickness levels, clients can achieve high-quality, long-lasting brass jewelry customization with the help of a Custom Brass Jewelry Manufacturer.

Whether for individual custom pieces or wholesale brass jewelry production, paying attention to plating thickness, surface treatment, and inspection methods can significantly improve jewelry quality and wearing experience. Partnering with a professional manufacturer like Fulcol helps find the best balance between appearance, durability, and cost, ensuring truly high-end and reliable brass jewelry customization.