Table of contents

Understanding Jewelry Electroplating

- Core role of electroplating:

Brass itself is prone to oxidation. Electroplating not only provides color to the jewelry but also improves wear resistance and corrosion protection. It is essential for all high-quality custom brass jewelry. - Principle and methods of electroplating:

Through metal ions in the electrolyte depositing on the brass surface, a stable plating layer is formed. Plating thickness is usually between 0.03–0.1 microns. High-end products often use multilayer structures to enhance durability. - Process standards and controllable factors:

Polishing, cleaning, and activation before plating are crucial for adhesion. Any error in these steps may cause uneven color or fading, reflecting the manufacturer’s technical level.

Common Electroplating Colors for Custom Brass Jewelry and Their Characteristics

- Gold color:Ranges from light gold to warm gold, giving a premium metal appearance. Suitable for high-end products in European, American, and Middle Eastern markets, but requires strict process control to ensure uniform color.

- Rose gold:Obtained by adding copper elements in the plating layer, producing a soft, natural pink tone. Especially suitable for women’s jewelry or light luxury brands, but sensitive to sweat and cosmetics, so protective coatings are essential.

- White gold / Rhodium color:Cool-toned with high reflectivity, highlighting the jewelry’s lines. Rhodium plating has high hardness, making it wear-resistant on rings and bracelets, commonly used in modern minimalist designs.

- Special colors (black gold, gunmetal, vintage copper):Require multiple plating steps or special treatments. High visual recognition, suitable for trendy or limited editions, but process control must be precise.

- Application scenarios:Different colors suit different jewelry types (necklaces, rings, earrings, bracelets). Designers should consider overall style and wearing experience in the early design stage.

Factors to Consider When Choosing Electroplating Colors

When customizing brass jewelry, selecting the right electroplating color affects not only appearance but also wearing experience and overall style. Key factors to consider:

- Skin tone and overall style: Different skin tones match different metal colors. Warm-toned skin works well with gold or rose gold plating, giving a soft, natural look; cool-toned skin pairs better with white gold, silver, or rhodium plating, emphasizing simplicity and modern style. Ultimately, personal preference should guide the choice to ensure comfort and style consistency.

- Frequency of wear and usage scenarios: Daily-wear jewelry encounters sweat, cosmetics, and friction. It is better to choose durable plating such as rhodium or PVD-treated layers to maintain color stability. Occasional wear jewelry can prioritize creativity and visual impact, such as black gold or vintage plating.

- Durability and maintenance: Certain colors, like black or vintage copper, are striking but may wear or fade over time. Consider post-care options, such as re-plating or protective coatings, to extend the jewelry’s lifespan.

- Skin sensitivity and allergy risk: Some plating contains nickel or other alloys, which may irritate sensitive skin. For sensitive individuals, low-allergy options like rhodium or high-quality gold plating are recommended.

- Brand style and market positioning: For brand collections, color should align with overall style. Light luxury brands may prefer rose gold or white gold tones, while trendy or niche brands can experiment with black gold or gunmetal to differentiate their visual identity.

Advanced Electroplating Techniques and Customization Process

Electroplating Techniques

Electroplating technology is key to the appearance and performance of brass jewelry. Different techniques affect color, gloss, wear resistance, and overall quality. Common techniques include:

- Traditional Electroplating: The most common method, suitable for gold, silver, and rhodium plating. Cost-effective, mature process, with stable color. Adjusting current, plating solution composition, and time can achieve different gloss levels and thicknesses.

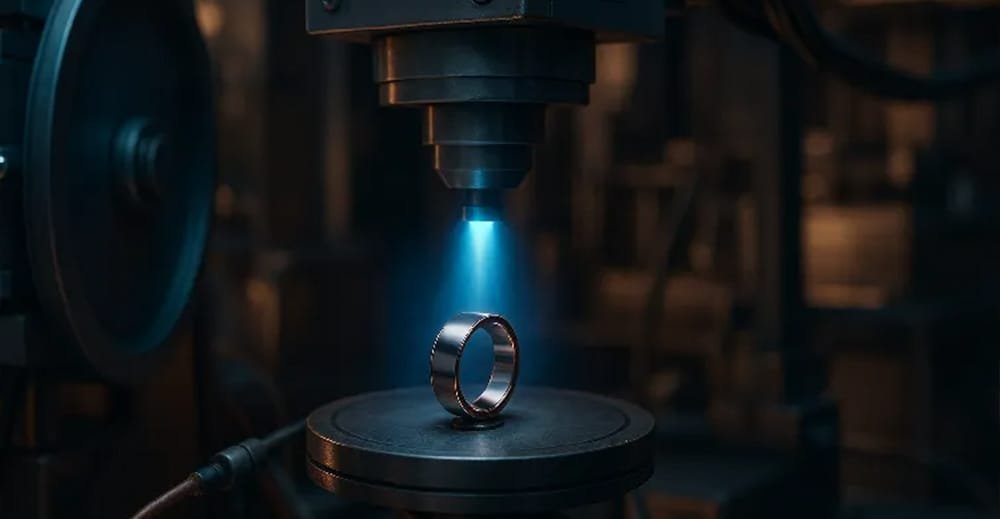

- Physical Vapor Deposition (PVD): A high-end process where metals evaporate in a vacuum and deposit on the jewelry surface, forming a dense layer. Offers high wear resistance and a wide range of colors, including blue, rainbow, and gunmetal tones. Ideal for fashion-forward or high-durability custom brass jewelry.

- Enamel Technique: Often combined with electroplating to create bright colors and glossy effects. Suitable for bold statement pieces. Enamel requires high-temperature firing; color is stable but layer thickness must be precisely controlled relative to the base metal and plating.

- Oxidation Treatment: Used to create vintage, matte, or blackened effects, such as black gold or antique silver. Adds personality but may fade with wear; periodic maintenance or protective coating is recommended.

Customization Process

Creating brass jewelry with exclusive electroplating colors requires following a standard process:

- Selecting the base material: Brass, copper, or stainless steel are common. Material choice affects plating adhesion, color rendering, and wear resistance.

- Determining electroplating color and surface effect: Choose the plating color and decide on enamel, matte, or vintage finishes based on brand positioning or personal preference.

- Technical consultation and feasibility assessment: Discuss process limits, plating thickness, and durability with the manufacturer. Multi-layer plating enhances durability; PVD is ideal for frequently worn items.

- Cost and delivery time confirmation: Complex techniques or special colors may increase cost and production time. Confirm budget and delivery schedule in advance to ensure smooth execution.

- Sampling and mass production: After sample approval for color, gloss, and texture, move to mass production. A professional Custom Brass Jewelry Manufacturer will conduct color consistency checks, wear resistance, and gloss testing to ensure batch products match samples.

Fulcol’s Professional Advantages in Custom Jewelry Electroplating

Since its establishment in 2004, Fulcol has specialized in high-quality gold, silver, and brass jewelry customization and wholesale production. As an experienced Custom Brass Jewelry Manufacturer, Fulcol has notable advantages in electroplating color customization:

- Extensive experience and professional team: With 22 years of jewelry manufacturing experience, the team consists of designers, technicians, and production experts. They transform creative designs into market-ready high-quality custom brass jewelry. Professional guidance and technical support are available for both classic and trendy designs.

- Advanced equipment and diverse plating techniques: With a 26,000-square-meter factory and precision electroplating equipment, Fulcol can achieve gold, silver, rhodium, PVD high-durability layers, and special colors such as black gold, rose gold, and vintage copper, ensuring uniform color and stable gloss.

- Flexible customization and low minimum order quantity: Fulcol provides fast sample production, personalized engraving, and packaging services, supporting orders from single pieces to mass production. Low MOQ suits emerging brands or small businesses and allows flexibility in responding to market changes.

- Strict quality control: Each piece undergoes thickness measurement, wear resistance, sweat resistance, and color difference testing to ensure batch products match samples and comply with international standards and export requirements.

- Comprehensive brand support: Offers 3D modeling, creative design, brand engraving, and custom packaging to help retailers, independent designers, and subscription box businesses build unique series smoothly.

- Sustainable and eco-friendly practices: Uses nickel-free, lead-free, or recyclable materials, and plating processes adhere to sustainability principles, balancing aesthetics and environmental responsibility.

- Industry trust and reputation: Fulcol has partnered with over 1,200 domestic and international brands, releasing 10+ new designs annually, with a production value of 60–80 million RMB (up to 100 million RMB). With experience, equipment, and professional service, Fulcol ensures efficient delivery and consistent quality for custom brass jewelry.

| Start Your Custom Order | Email: info@fulcol.com | Number:+86-18876512305 |

Electroplating color is not only a choice of appearance but also an essential element for brand quality and wearing experience. Selecting the right color requires considering market, usage, safety, cost, and long-term brand strategy.

Through scientific process control, multilayer plating, and professional testing, customized jewelry can achieve the optimal balance between aesthetics and durability. Partnering with an experienced manufacturer, especially a Custom Brass Jewelry Manufacturer like Fulcol, ensures that your brass jewelry achieves the desired effect from design to finished product.