Table of contents

Fulcol’s Core Advantages as a Custom Brass Bracelet Manufacturer

1. Over 20 Years of Manufacturing Experience

Since its establishment in 2004, Fulcol has focused on high-quality metal jewelry manufacturing, accumulating more than twenty years of industry experience. The company combines traditional craftsmanship with modern technology, mastering the design, casting, and plating processes of various brass jewelry, enabling efficient transformation from concept to mass production.

2. Professional Design and Technical Team

Fulcol has a team of experienced designers and technical experts skilled in 3D modeling, engraving, and structural optimization. Each year, the team develops thousands of original designs for global clients and provides trend consultation and sample prototyping, helping brands create products with both artistic value and market appeal.

3. Strict Quality Control System

Every bracelet undergoes multiple inspections, including measurements, surface finish, plating adhesion, and corrosion resistance testing. All production processes comply with ISO international standards, ensuring durability and consistency for each batch.

4. Flexible Customization and Order Quantities

Fulcol offers flexible production options, from small batch samples to large-scale OEM production. The minimum order quantity is as low as 50 pieces, with rapid prototyping available based on design complexity, allowing emerging brands to enter the market with minimal barriers.

5. Environmentally Friendly and Sustainable Production

Fulcol adheres to nickel-free and lead-free plating and uses recyclable materials, supported by advanced wastewater treatment and energy-saving equipment. All brass raw materials come from certified suppliers, ensuring compliance with environmental regulations and maximizing material utilization.

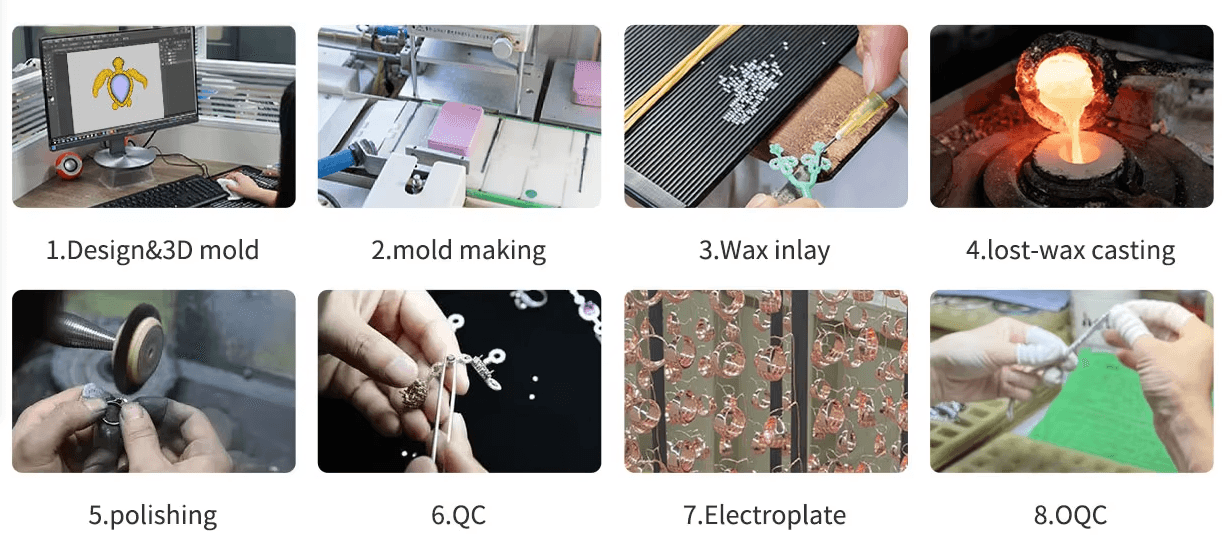

Complete Process for Custom Bracelets: From Idea to Finished Product

- Design Concept and Creative Communication: The process begins with communication between the client and Fulcol’s design team. Based on brand positioning, style requirements, and market trends, we provide professional suggestions and sketch concepts to ensure the design direction accurately meets client goals.

- 3D Modeling and Prototype Production: Once the design is finalized, designers use 3D modeling technology to visualize the idea and optimize structure and proportions. High-precision prototypes are then created to verify the shape and wearing comfort.

- Material Selection and Process Confirmation: During the sample approval stage, clients can choose different brass materials, plating colors, and surface treatments such as polishing, brushing, or vintage textures. Fulcol recommends the most suitable production method according to the design to ensure both aesthetics and durability.

- Mass Production and Quality Inspection: After sample approval, the order enters mass production. All processes, from casting, polishing, plating to assembly, are completed in-house with inspection points at every step. Each batch undergoes appearance, dimension, and wear-resistance tests to ensure consistency.

- Brand Packaging and Delivery: After quality inspection, products move to packaging. Fulcol provides branded labels, custom boxes, and eco-friendly packaging solutions, ensuring that the finished products meet brand image and international shipping standards. All orders are delivered on time with complete tracking and after-sales support.

Quality, Safety, and International Standards

In high-end jewelry manufacturing, quality is the lifeline of a brand. Fulcol adheres to the principle of defining excellence by standards, implementing strict controls from raw materials to finished products.

- International Certifications and Testing: Fulcol has obtained ISO9001 quality management system certification and ROHS environmental compliance certification, working with third-party testing agencies such as SGS to conduct regular material safety inspections. All products are free of nickel, lead, and other harmful substances, meeting health standards for the EU and North American markets.

- Material and Plating Safety: The brass used is high-purity copper-zinc alloy, verified by spectrometer analysis to ensure stability and malleability. Plating materials use eco-friendly precious metal solutions to reduce chemical residue. Products undergo 48-hour salt spray and 72-hour constant temperature and humidity tests to verify oxidation resistance and color durability.

- Quality Control and Traceability System: Fulcol has established a batch tracking system from raw materials to finished products. Inspection reports and test data are stored for over three years for client audits.

- Case Study: For example, Fulcol developed an eco-friendly gold-plated brass bracelet series for a European client. The plating color variation was controlled within ±1.5% and passed SGS tests, earning the client’s annual “Outstanding Supplier” award. These rigorous standards are a key reason why Fulcol remains competitive in the global custom brass jewelry manufacturer market.

Trends and Design Inspirations in Brass Bracelets

Design is the soul of jewelry, and trends guide manufacturing. As an experienced custom bracelet manufacturers, Fulcol tracks global market and cultural trends, combining artistic creativity with consumer data to provide design inspiration for brands.

Global Design Trends

- Minimalism: Clean lines, light luxury style, suitable for modern urban brands.

- Vintage Engraving: Relief or engraved patterns to showcase classic elegance.

- Stackable Designs: Emphasizes layered wearing and versatile combinations.

Technology Trends: AI and 3D Printing

Fulcol uses AI-assisted design systems to predict popular patterns based on market feedback. 3D printing allows designers to quickly prototype complex structures, significantly shortening the design cycle.

Plating and Color Innovations

Popular plating colors include rose gold, 18K gold, silver, and black titanium. Fulcol’s unique dual-tone plating (e.g., gold+black, silver+gold) enhances visual depth and modern appeal.

Professional Design Advice

Fulcol guides brands in design according to regional market preferences: European and American markets favor subtle metallic shine and engraving, while Southeast Asia prefers bright gold and gemstone inlays. Data-driven trend analysis helps clients precisely target their audience.

Fulcol Bracelet Customization Services and Advantages

As a leading custom bracelet manufacturers, Fulcol offers comprehensive customization services from concept to finished product, providing brands with design flexibility and rapid market response capabilities.

1. Customizable Elements

- Material Selection: Various metals such as silver and brass are available, allowing selection based on design requirements for suitable hardness and texture.

- Surface Finishes: Polishing, brushing, vintage, matte, and other finishing options are available to meet diverse style preferences.

- Plating and Color Options: Single or dual plating in 18K gold, rose gold, silver, black titanium, etc., ensuring long-lasting color and visual depth.

- Design Details: Engraving, gemstone or crystal inlay, personalized text, and logo customization create unique brand identity.

- Packaging and Brand Presentation: Customized boxes, branded logos, and eco-friendly packaging solutions enhance brand image and comply with international shipping standards.

2. Customization Advantages

- Flexible Minimum Order and Rapid Prototyping: The minimum order quantity is typically 50-100 pieces per style/color, depending on design complexity. Fulcol discusses specific requirements with you to develop the optimal solution, while also supporting rapid sample production to accelerate design validation and market testing.

- Professional Design and Technical Support: 3D modeling, structural optimization, trend analysis, and professional guidance ensure designs are both aesthetically pleasing and market-competitive.

- Strict Quality Control: Multiple quality inspection stages guarantee dimensions, surface finish, plating adhesion, and corrosion resistance meet international standards.

- Comprehensive One-Stop Service: From design communication to mass production, packaging, and logistics, every project is managed to ensure efficient and worry-free delivery.

- Innovation and Brand Collaboration: Market trend analysis and collection development support help clients continuously optimize products and build a distinctive brand identity.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

With over 20 years of industry experience, Fulcol is not only a leading Custom Brass Jewelry Manufacturer but also a trusted partner for global brands. We combine artistic design with precise craftsmanship, offering professional support and flexible customization from concept to mass production. Whether you are an emerging brand or an established jewelry company, Fulcol delivers high-quality, sustainable, and innovative solutions to help your collections stand out in the global market. Choosing Fulcol ensures your jewelry ideas shine with perfect quality and market appeal as a top-tier custom bracelet manufacturers.