When a piece of gold jewelry gently passes over the neck or fingertips, it not only exudes a golden luster, but also carries confidence and elegance. Different gold plating processes such as gold filling, gold vermeil and ordinary electroplating are like three artists with their own strengths, giving life to the same piece of metal in different ways: some retain the true nature of gold in a heavy and lasting way, some use the pure silver base to make the luster brighter, and some rely on flexibility to meet fashion trends.

For gold jewelry manufacturers like Fulcol, who are good at customizing and producing K gold, silver and brass jewelry, a deep understanding of the production principles, texture differences, usage experience and maintenance points of these three processes can not only help customers make more appropriate choices, but also make products stand out in the fiercely competitive market.

Table of contents

What is Gold Filled?

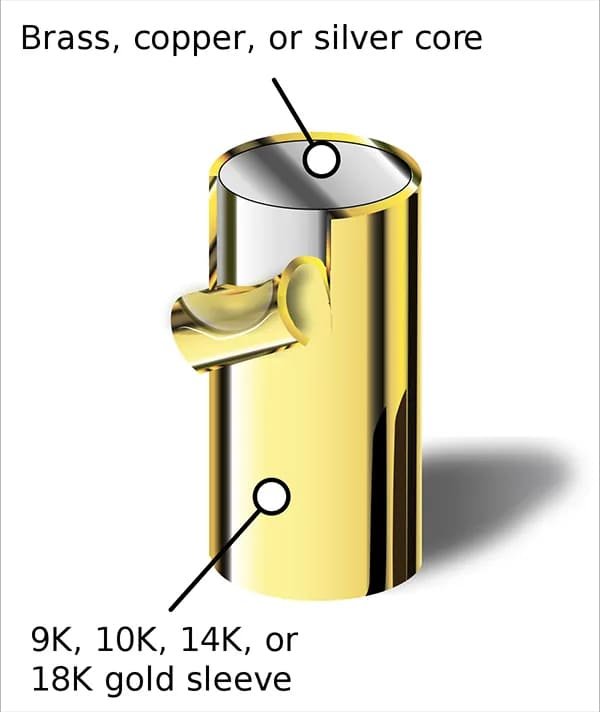

Gold Filled is not simply a thin layer of gold foil, but a process that closely combines a thicker gold layer with a metal base.

Overview of the production process

Prepare the base: First, choose copper or brass, clean and polish it to make the surface smooth and free of impurities.

Stacking gold foil: Spread a layer of gold foil on both sides of the base, the thickness is usually around 40-80 microns.

High-temperature pressing: Put the stacked “gold foil-base-gold foil” sandwich structure into a hot press, and apply strong pressure at a high temperature of about 200℃ to make the gold layer and the base combine at the molecular level.

Polishing and forming: Finally, remove the excess edges and polish to a smooth mirror surface, showing a color very similar to solid gold.

User experience and features

Wear-resistant and durable: Because the gold layer is thicker, the surface can still maintain its luster after years of daily wear, and only slight fine lines will appear.

Anti-allergic: The part that contacts the skin is covered with high-purity gold, which can effectively reduce the risk of metal allergies.

Warm texture: The color is soft and not too dazzling, but it can still show elegance and nobility.

Daily maintenance tips

After wearing, wipe gently with a clean, soft, lint-free cloth to remove sweat stains and dust.

Avoid direct contact with chemicals such as perfume and detergent.

When storing, place in a sealed bag or jewelry box, away from moisture and bright lights.

What is Gold Vermeil?

Gold Vermeil (Vermeil) is the electroplating of gold on the surface of pure silver (925 sterling silver), through the combination of “silver base + gold layer”, to create a bright and high-end effect.

Brief description of electroplating process

Pretreatment of silver jewelry: First, ultrasonically clean and acid-wash the silver pieces to remove oxides and dirt to ensure a clean surface.

Gold deposition: Place the silver pieces in an electrolyte containing gold ions, and use a certain voltage and current to make the gold ions evenly adhere to the silver surface to form a gold layer of at least 2.5 microns. In order to enhance durability, multiple electroplating can be performed to reach 3-5 microns.

Post-polishing: After electroplating, light polishing is performed to make the gold layer more uniform and smooth.

Gloss and texture advantages

Bright reflection: The pure silver base itself has excellent reflective properties, making the gold layer appear particularly shiny under the light.

More advanced texture: Compared with ordinary electroplating, Vermeil’s gold layer is thicker, and the underlying silver is integrated into the luster, presenting a visual effect close to solid gold.

Maintenance points

Use warm water and neutral hand soap to clean, and use a soft brush to gently scrub the fine seams.

Avoid soaking in chlorine or sulfur-containing environments (such as swimming pools, household bleach) for a long time.

It can be stored in an anti-oxidation sealed bag at ordinary times to delay the sulfidation of the underlying silver.

What is Gold Plating?

Gold Plating is the most common surface decoration method. The metal base (such as stainless steel, copper or alloy) is electrolyzed to form a thin layer of gold film.

Basic process

Substrate treatment: First use pickling or primer treatment to remove the oxide layer on the metal surface to improve adhesion.

Electroplating deposition: Immerse the body in gold electrolyte, pass low voltage and a certain current, and the gold ions are gradually deposited on the substrate.

Rinse and polish: After the electroplating is completed, rinse with clean water and lightly polish to obtain a smooth appearance.

Features and applicable scenarios

Diverse styles: Ability to quickly switch gold plating formulas to produce a variety of tones such as gold and rose gold.

High production efficiency: Short electroplating time and low cost, suitable for large-scale, fashionable and fast-moving jewelry.

Thin film layer: The gold layer is usually from a few hundred nanometers to 1-2 microns. When wearing it, be careful to avoid long-term friction with hard objects or chemicals.

Daily care recommendations

Avoid collision with hard objects or penetration of small scratches.

It is recommended to remove it when doing housework or exercising to prevent contact with detergents and sweat.

Wipe the surface with a soft dry cloth frequently and keep it dry for storage.

Differences between Gold Filled, Gold Vermeil and Gold Plating

| Features | Gold Filled | Gold Vermeil | Gold Plating |

| Base metal | Copper, brass | 925 sterling silver | Stainless steel, copper, alloy, etc. |

| Gold layer thickness | About 40–80 microns | ≥2.5 microns (common 3–5 µm) | 0.1–2 microns |

| Durability | No noticeable wear for many years | Maintains luster for several years | Easy to wear in a few months to a year |

| Anti-allergy | High | Good | Depends on the base material |

| Gloss | Warm and natural | Bright and reflective | Various tones |

If you value long-term wear and reduce allergies, you can give priority to Gold Filled. If you pursue brightness and cost, Gold Vermeil is a good compromise. If you need more styles and faster launch, Gold Plating can meet diverse needs.

How to distinguish between Gold Filled, Gold Vermeil and Gold Plating

Whether in quality inspection or customer acceptance, it is very important to quickly and accurately identify the process. Here are some simple and easy methods:

Marking identification

Observe the marking of the jewelry:

- “GF” or “RGP” (Rolled Gold Plate) → Gold Filled

- “925” + “Vermeil” → Gold Vermeil

- “GP”, “EP” → Gold Plating

Friction color test

Use a piece of soft cloth or denim to rub back and forth dozens of times on the hidden part of the jewelry to see if the base color is revealed. Gold Filled and Vermeil usually do not show through the bottom due to the thicker gold layer; while electroplated gold is more likely to reveal the metal underneath.

Acid pen test

Lightly draw a small line in an inconspicuous area, and then drop metal test liquid representing different purities respectively. Gold Filled and Vermeil remain golden at their corresponding acidity, while ordinary electroplating often fades quickly.

Will gold plating fade?

Any surface gold plating process will inevitably fade gradually due to friction, chemicals and environmental factors. The following are the main factors that affect the fading speed and the corresponding methods:

Friction factors: When the gold layer is repeatedly in contact with the skin, clothing or hard objects, it will gradually wear out. Avoid long-term friction with rough surfaces in daily life, and wrap it in a soft cloth when storing.

Chemical factors: The acid and alkaline components of perfume, detergent, bleach, and sweat will cause chemical corrosion to the gold layer. Try to wait for perfume and hand cream to dry before wearing, and take off the jewelry when doing housework or swimming.

Environmental factors: Hydrogen sulfide in the air or high humidity will cause the base or plating of pure silver to appear slightly dark. Store with desiccant or moisture-proof bags, and wipe it regularly with a soft cloth.

Other types of gold jewelry

In addition to the above three mainstream processes, there are some emerging or composite technologies to meet special needs:

Solid Gold: From 10K to 24K, it does not fade and is not easy to be allergic, but the cost and deformation risk are higher.

PVD vacuum coating: metal is evaporated in a vacuum environment and deposited on the surface of the jewelry to form a dense film layer, which can be customized in color and is more wear-resistant.

Composite coating: electroplating is combined with ceramic, polymer and other coatings to achieve both scratch resistance and glossiness, suitable for sports or heavy wear scenarios.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

If you need a classic that will accompany you for many years, Gold Filled will win your favor with its solid gold layer and comfortable wearing experience. If you love bright and shining luster and want to get good texture at a mid-range price, Vermeil is an ideal choice. If you love style updates and free matching, then the light and flexible electroplated gold can continue to satisfy your fashion desires.

In the Fulcol customization or production process, combined with customers’ different needs for durability, glossiness and style update frequency, choose the most suitable gold plating process, and provide a simple identification and maintenance guide, which will surely make your products more competitive in the market and let every wearer feel exclusive dignity and intimacy. Choosing Fulcol as your gold jewelry supplier will become your reference in the world of jewelry, injecting lasting charm into each piece of gold jewelry.