Table of contents

- What is Electrophoretic Coating and How Does It Work on Brass Jewelry?

- Step-by-Step Electrophoretic Coating Process for Brass Jewelry

- Common Tools, Materials, and Recommended Techniques

- Electrophoretic Coating vs Other Protection Methods

- Jewelry Supplier Selection Criteria and E-Coating Comparison

- Common Problems and Solutions in Electrophoretic Coating

What is Electrophoretic Coating and How Does It Work on Brass Jewelry?

Electrophoretic coating (E-coating) is an advanced surface finishing process that uses an electric field to deposit charged paint particles uniformly on a metal surface, forming a transparent or colored protective layer. Its use in brass jewelry is increasingly popular due to its effectiveness and precision.

1. Basic Principle

- The coating particles carry an electric charge and are attracted to the jewelry surface under the electric field.

- The deposited layer is uniform and dense, covering even intricate designs and details.

2. Relation to Brass

- Brass is a copper-zinc alloy that is strong but prone to oxidation and tarnishing.

- The E-coating acts as an invisible shield, preventing corrosion and discoloration while preserving the natural metal texture.

3. Unique Advantages

- The coating is thin and transparent, preserving the jewelry design

- Provides durability and corrosion resistance for daily wear

- Highly controllable process, ideal for brass jewelry manufacturers in large-scale production.

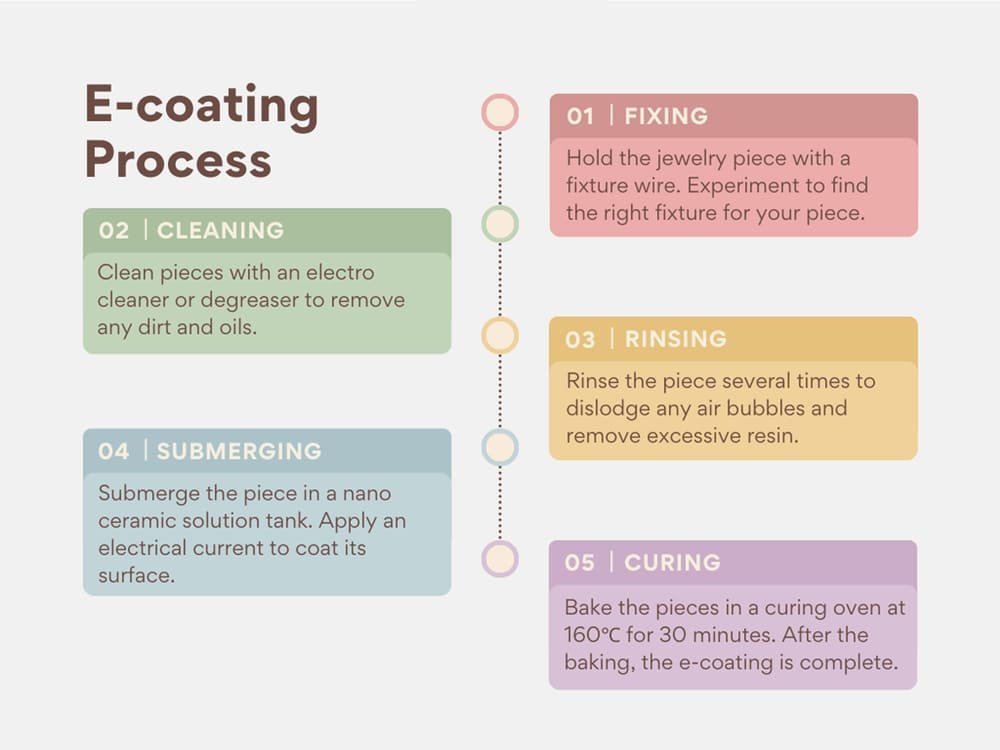

Step-by-Step Electrophoretic Coating Process for Brass Jewelry

Electrophoretic coating is a precise system. Improper handling can result in peeling or yellowing even on expensive pieces. Standard steps include:

1. Surface Cleaning and Pretreatment

- Degreasing: Remove oils and polishing residue using alkaline cleaners or ultrasonic cleaning

- Acid activation: Light acid etching enhances adhesion

- Rinse: Ensure no chemical residues remain to avoid uneven coating.

2. Electrophoretic Deposition

- Voltage control: Typically 30–150V, adjusted according to item size and desired thickness

- Time control: Deposition lasts 1–3 minutes; excessive time may cause cracking

- Temperature & pH: Maintain 20–30°C, pH 5.5–6.0 for uniform deposition.

3. Curing and Drying

- Bake at 150–180°C for 20–30 minutes

- The process cross-links coating molecules, enhancing hardness, abrasion resistance, and adhesion.

4. Professional Tools and Materials

- Industrial electrophoretic tanks, DC power supplies, temperature and circulation control

- Eco-friendly water-based E-coating paints

- Gloss meters and adhesion testing equipment.

By following these steps, a custom brass jewelry manufacturer can ensure each piece has a uniform, transparent, and durable coating.

Common Tools, Materials, and Recommended Techniques

Coating quality depends not only on the process but also on the equipment, materials, and testing methods used:

1. Equipment

- Industrial E-coating tanks for large-scale production, ensuring stable current and temperature

- Small workstations for designer brands or limited custom runs

- Filtration and circulation systems to maintain paint purity and avoid contamination.

2. Material Selection

- Eco-friendly water-based E-coating paints free of VOCs, compliant with RoHS and REACH

- Transparent or colored coatings: transparent preserves brass appearance; colored options allow antique black, rose gold, or other decorative effects.

3. Quality Testing Methods

- Hardness testing: pencil hardness method to assess scratch resistance

- Adhesion testing: cross-cut test for coating strength

- Salt spray testing: high-quality coatings withstand ≥240 hours in saline environments without visible corrosion.

Electrophoretic Coating vs Other Protection Methods

Common methods include plating, spray painting, clear lacquer, and electrophoretic coating. Comparison:

| Method | Advantages | Disadvantages | Suitable For | Durability (Salt Spray Test) |

|---|---|---|---|---|

| Plating | Decorative, multiple color options | Thin, wears easily, may contain heavy metals | High-end jewelry | 24–72 hours |

| Spray paint | Low cost, simple process | Peels easily, low abrasion resistance | Fast-moving consumer items | <48 hours |

| Clear lacquer | Preserves metal appearance, easy application | Yellowing, weak adhesion | Crafts, temporary protection | ~72 hours |

| Electrophoretic coating | Uniform, eco-friendly, durable, batch consistency | High equipment cost, process control required | Mid- to high-end brass jewelry | ≥240 hours |

📌 Insight: E-coating offers superior durability, environmental compliance, and consistency, making it the preferred process for modern brass jewelry manufacturers.

Jewelry Supplier Selection Criteria and E-Coating Comparison

When collaborating with international brands and designers, E-coating quality directly affects order compliance and delivery. Key supplier evaluation points:

- Coating consistency: Thickness, gloss, and color variation across batches

- Standardized procedures: SOPs, quality records, and equipment maintenance

- Environmental compliance: SGS, REACH, and RoHS certifications

- Process versatility: Support transparent, matte, colored, and composite coatings

- Sampling and after-sales: Quick prototyping, coating thickness adjustment, and custom finish development

Common Problems and Solutions in Electrophoretic Coating

Even with standardized procedures, some issues may occur:

- Bubbles or pinholes: Caused by inadequate surface cleaning or paint contamination; solution: enhance pretreatment and maintain filtration

- Coating peeling: Due to insufficient acid etching or inadequate curing temperature; solution: control acid etch time and baking conditions

- Uneven color: Caused by unstable voltage, time, or pH; solution: standardize parameters and calibrate equipment regularly

- Reduced corrosion resistance: Caused by low-quality paint or uneven thickness; solution: use compliant water-based E-coating paint and ensure uniform film thickness.

Proactive testing and process optimization enable a custom brass jewelry manufacturer to minimize defects and maximize customer satisfaction.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

Electrophoretic coating is not only a protective technique for brass jewelry but also a reflection of supply chain stability and brand value. With increasing demand for durability and environmental compliance, more manufacturers are adopting E-coating as a core process. Whether for large-scale production or small-batch customization, brass jewelry manufacturers and custom brass jewelry manufacturer benefit from its superior protection, consistency, and aesthetic quality.