When you buy a shiny gold plated jewelry, have you ever wondered what secrets are hidden behind it? The glittering jewelry on the surface may not be as durable, authentic or worth the money as you think. For those of you who are looking for wholesale gold plated jewelry or want to establish a partnership with a gold-plated jewelry manufacturer, it is important to understand the true situation of gold plating.

Many consumers and wholesalers think that “gold plating is gold plating”, but in fact, this is just a general term. The raw materials, technology and standards used by different manufacturers may vary greatly. The thickness of the plating, the purity of the gold, the choice of the electroplating substrate, whether the electrophoretic coating is in place… These seemingly insignificant technical details directly affect the luster, durability and fading of gold-plated jewelry.

As a professional gold plated jewelry manufacturer, Fulcol reveals some industry insider information that gold-plated jewelry manufacturers may not actively tell you, helping you identify high-quality products, avoid unnecessary losses, and choose a trustworthy partner.

Table of contents

Gold plating thickness: meeting standards or cutting corners?

In the gold plating industry, the thickness of the coating is a core indicator, which is directly related to the appearance retention time and wear resistance of the jewelry. Generally speaking, the thicker the gold plating layer, the longer its service life and the longer the color retention. There are certain reference standards for the thickness of gold-plated jewelry internationally:

- Flash Plating: The thickness is less than 0.175 microns, which is only suitable for very short-term wear.

- Micron Plating: 1 micron to more than 3 microns, which belongs to a higher quality grade and can be maintained for months or even longer.

However, some irresponsible manufacturers will cut corners to reduce costs, claiming to be “thick gold plating”, but the actual coating is even less than 0.1 microns. This kind of product will expose the base metal after wearing it a few times, and there will be problems such as fading, oxidation or skin allergies.

In terms of identification methods, as a purchaser, you can use a professional XRF tester to detect the thickness of the coating, or communicate with experienced manufacturers to clarify the process parameters. In customized wholesale orders, Fulcol will recommend the appropriate thickness based on customer usage needs, and display the electroplating process openly and transparently to prevent stealing thinness and lightness.

Gold used: real or fake?

Gold plating is not the same as gold. Most gold-plated jewelry uses 24K or 18K pure gold solution as the raw material for electroplating, but some manufacturers use “gold alloy liquid” doped with other metals to replace real gold in order to reduce costs. This alternative looks similar in the short term, but will fade faster after long-term wear and may cause skin discomfort.

Although real gold electroplating costs more, its color is warmer and more natural, and it has strong antioxidant capacity, making it more suitable for making high-end jewelry, wedding gifts or products that need to be worn for a long time. To ensure the authenticity of the raw materials used, Fulcol uses certified real gold plating liquid for all electroplating processes, and provides customers with raw material batch records and material certificates.

Consumers can initially judge the integrity of the manufacturer by asking how much karat gold is used for electroplating and whether there is a raw material certificate; wholesale buyers can also request to show the composition test report of the electroplating alloy liquid.

Metal selection and its impact on electroplating

Many people don’t know that the base metal (also called “substrate”) of gold-plated jewelry actually plays a decisive role in the quality of electroplating. Common substrates include copper, brass, stainless steel, silver, zinc alloy, etc.

- Copper and brass are the most common choices because of their low cost and strong processability, but their corrosion resistance is poor.

- Stainless steel is more durable, but its adhesion is slightly inferior.

- 925 sterling silver is the base of high-end gold-plated jewelry, which is not only wear-resistant but also more skin-friendly.

Cheap alloys such as zinc alloys are prone to blistering and peeling during the electroplating process, and are not tightly bonded to the gold layer. They are one of the least recommended substrates. If you are engaged in the wholesale business of gold-plated jewelry, be sure to confirm whether the manufacturer has stated which metal is used as the base material and whether it has been pre-treated for corrosion protection, such as nickel-plating the bottom layer of copper to enhance bonding strength.

During the manufacturing process of Fulcol, all metal substrates will undergo multiple degreasing, cleaning, neutralization and activation steps to ensure that the coating is firmly attached and extend the service life of the jewelry.

Electroplating thickness test: visible guarantee

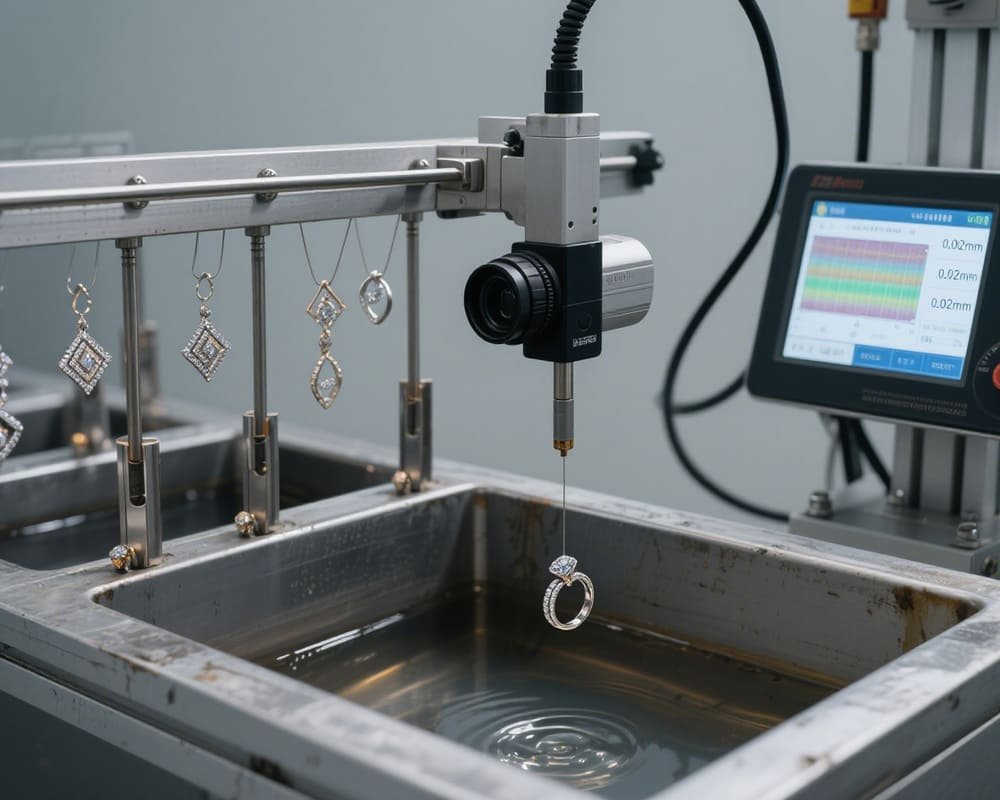

You may have heard that “gold-plated jewelry with a test report is reliable”, and this is not groundless. In the jewelry industry, commonly used coating thickness detection equipment includes X-ray fluorescence (XRF), optical microscope, electrolytic stripping instrument, etc.

Among them, XRF non-destructive testing is the most common and efficient method. It can quickly and accurately display the thickness and elemental composition of each layer of metal on the metal surface without damaging the sample. Large gold-plated jewelry manufacturers are usually equipped with such equipment, especially when producing for overseas markets.

However, due to cost constraints, some foundries or small workshops do not test every batch of products, but only sample some or even skip the test directly. The result is that different batches of products are of different thicknesses and unstable quality.

Fulcol always insists on sampling thickness testing for each batch of large goods and records it. We encourage customers to make testing requirements to establish a transparent and traceable quality control system.

Electrophoretic coating and palladium layer: hidden factors affecting durability

Even if the coating itself is thick enough, if there is no post-treatment process, gold-plated jewelry is still prone to discoloration due to air oxidation and sweat erosion. Electrophoretic coating and palladium layer treatment are important steps to improve the durability of gold-plated jewelry.

Electrophoretic coating (E-Coating) uses electric current to make a transparent coating evenly adhere to the surface of jewelry. This coating will hardly affect the color and gloss of the jewelry, but it can effectively isolate oxygen and moisture and delay oxidation. Palladium is often used as a protective coating before gold plating, which can prevent impurities in the substrate from migrating to the surface, and play a role in preventing fading and allergies.

Many cheap wholesale gold-plated jewelry do not have an electrophoretic layer or a palladium base. The color is bright when they are just bought, but they become obviously darker and lose their luster after a few weeks. When Fulcol customizes high-end gold-plated products, it will add a transparent electrophoretic layer and a palladium base protection according to the purpose to extend the wearing life.

When purchasing, you can directly ask whether the product has an electrophoretic sealing layer and a palladium base treatment process. Experienced manufacturers will definitely explain its advantages and operating details in detail.

FAQ

Is gold-plated jewelry easy to fade?

Not necessarily. High-quality gold-plated jewelry can maintain its luster for 6 months to more than 2 years under reasonable maintenance. The key lies in whether the coating thickness, electroplating materials, and post-processing process are qualified.

How to judge whether a gold-plated jewelry manufacturer is reliable?

You can judge from whether its factory has XRF testing equipment, whether it can provide test reports, and whether it is willing to explain the materials and process flow.

What is the difference between gold plating and gold plating?

Gold plating refers to the thinner gold layer attached to the surface of the substrate through electroplating; while gold plating is a thicker layer of metal mechanically pressed on the surface of the substrate, which is more durable.

How to extend the service life of gold-plated jewelry?

Avoid contact with chemicals such as perfume, sweat, detergent, etc., wipe with a clean soft cloth after wearing, avoid collision with hard objects, and store separately in a sealed state.

What gold-plating customization services can Fulcol provide?

We support plating of 18K, 24K, rose gold and other colors of gold layers, and the substrates can be copper, 925 silver, stainless steel, etc. We support high-end needs such as batch customization, laser logo, electrophoresis treatment, multi-layer electroplating and thickening.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

The world of gold-plated jewelry is far more complicated than you think. Beneath those seemingly shiny surfaces, there are multiple processes such as materials, electroplating technology, post-processing and quality inspection, and each link is related to the quality of a piece of jewelry. As a gold-plated jewelry manufacturer, Fulcol is committed to providing customers with trustworthy wholesale gold-plated jewelry solutions with real materials, strict process standards and responsible services.

If you want to find a professional and transparent partner, we welcome you to contact Fulcol to jointly create high-quality, long-lasting gold-plated jewelry products.