Table of contents

- Overall Framework of OEM Silver Jewelry Quality Control

- Plating Thickness Inspection and Control Methods

- Solder Joint Strength Inspection and Improvement

- Stone Setting Inspection and Precision Standards

- Surface Treatment and Final Inspection

- Fulcol’s Continuous Quality Improvement: Full-Process Control from Factory to Customer

Overall Framework of OEM Silver Jewelry Quality Control

In the OEM manufacturing of 925 sterling silver bracelets and bangles, establishing a comprehensive quality control system is crucial. Fulcol, as professional custom bracelet manufacturers and silver bracelet manufacturers, strictly implements standardized processes at every stage of production. The core framework includes the following aspects:

- Quality Management System: Fulcol strictly follows international certification standards such as ISO 9001, covering process specifications, inspection procedures, and documentation. Every operation generates traceable records, from raw material procurement to finished packaging, ensuring the production process is controllable and standardized.

- Key Inspection Points: The core inspection points include plating thickness, solder joint strength, and the stability of stone settings. Data recording and statistical analysis form a closed-loop management system, ensuring that each batch of silver jewelry maintains consistency in appearance, durability, and structural stability.

- Factory Layout and Division of Labor: Welding, polishing, and stone-setting areas are independently arranged to reduce cross-contamination and human errors. Each station is equipped with professional inspection equipment and operated by experienced craftsmen to ensure every product meets the standards of silver bracelet manufacturers.

- Process Monitoring and Continuous Improvement: Regular audits of the production process are conducted to identify and solve issues promptly. By analyzing quality data, process parameters are optimized to improve overall production efficiency and product stability, ensuring every batch meets high-quality standards.

Plating Thickness Inspection and Control Methods

The plating layer directly determines the appearance and durability of silver jewelry. If the thickness is too thin, it may oxidize, fade, or wear; if too thick, it may affect comfort and stone setting precision. According to ASTM B488 standards, the plating layer of 925 sterling silver jewelry typically requires a thickness of 0.5–2 microns. Fulcol strictly controls plating thickness during production to ensure uniform luster and reliable durability.

In practice, Fulcol uses multiple tools and methods for thickness inspection:

- Micrometer gauges for quick local measurements on key surfaces.

- XRF (X-ray fluorescence analyzer) for non-contact precise measurement, suitable for batch inspection.

- Focused measurement on curved or stone-set areas to ensure uniform thickness.

Additionally, Fulcol uses 3D modeling and design data to evaluate plating coverage on complex shapes in advance, optimizing plating parameters. Each batch’s measurement data is recorded, and if deviations are found, plating current, solution concentration, or immersion time is immediately adjusted to ensure uniformity.

Solder Joint Strength Inspection and Improvement

Welding is a key step in assembling silver jewelry and directly affects the structural strength of bracelets and bangles. Common welding methods include spot welding, laser welding, and soldering, with laser welding widely used for its high precision and low heat impact. Fulcol strictly controls solder joint quality to ensure safety during wear.

Inspection methods include:

- Tensile Test: Measures the maximum load the joint can withstand, ensuring it does not loosen under daily wear or minor impacts.

- Shear Test: Evaluates the joint’s strength under shear force.

In practice, Fulcol combines professional welding equipment with 3D design models to ensure precise joint placement and appropriate joint size. Craftsmen clean surfaces before welding to prevent oxidation or residue from affecting quality. If defects such as incomplete welding, cold joints, or burnt joints are detected, production parameters are immediately adjusted. This process ensures every solder joint meets the standards of silver bracelet manufacturers.

Stone Setting Inspection and Precision Standards

The stone setting process directly affects the aesthetics and security of gemstones in silver jewelry. Common setting methods include prong, bezel, invisible, and dangle settings, each requiring different precision in welding, polishing, and stone stability. Fulcol ensures secure and reliable settings through scientific inspection and precise operations.

Inspection methods include:

- Vibration Test: Simulates minor impacts during wear.

- Tensile Test: Tests the holding force of the setting to ensure stones remain secure.

In practice, Fulcol evaluates stress on stone settings using 3D models, adjusting prong height, setting thickness, and edge smoothness to prevent stones from loosening or damage. Each gemstone is examined under a microscope, and multiple points of fixation are applied if necessary to enhance stability. These methods ensure silver jewelry meets both aesthetic and safety standards of custom bracelet manufacturers.

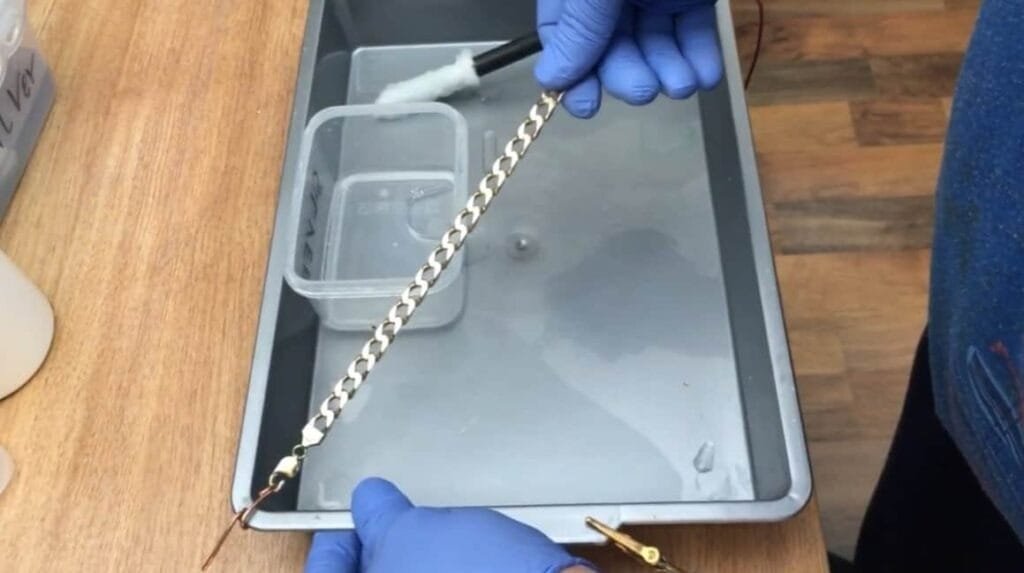

Surface Treatment and Final Inspection

Surface treatment is the final step in silver jewelry production, determining luster, texture, and overall appearance. Common methods include polishing, brushing, and post-plating treatments. Rigorous final inspection is required after treatment.

Fulcol’s final inspection process includes:

- Appearance Check: Using microscopes to examine scratches, dents, and oxidation.

- Color Consistency Check: Using colorimeters to ensure consistent color across batches or plating layers.

- Structural Check: Confirming solder joints, stone settings, and closures are intact.

Additionally, Fulcol compares 3D design data with actual products to ensure dimensions, shapes, and design details match the prototype. Each finished piece undergoes multiple inspections and sampling checks, ensuring every batch meets standards before delivery.

Fulcol’s Continuous Quality Improvement: Full-Process Control from Factory to Customer

At Fulcol, continuous quality improvement spans the entire production and customer delivery process, achieving full-process control from the factory to the client. This ensures every 925 sterling silver bracelet and bangle meets high standards while enhancing customer satisfaction and brand credibility.

- Standardized Full-Process Management: From initial design, 3D modeling, material selection, plating, welding, stone setting, to final polishing and packaging, Fulcol establishes strict operational standards. Each step has standard operating procedures and key quality checkpoints, ensuring batch consistency and traceability.

- Real-Time Data Monitoring and Analysis: Key metrics such as plating thickness, solder joint strength, and stone setting pass rates are recorded and analyzed, forming quantifiable reports. Deviations trigger immediate parameter adjustments for rapid correction and continuous optimization.

- Sustainable and Eco-Friendly Production: Fulcol applies recyclable materials, nickel-free and lead-free plating, and energy-saving processes to reduce environmental impact. Full-process control ensures product quality while supporting sustainable practices, providing reliable eco-friendly assurances to clients.

- Flexible Minimum Order Quantities and Rapid Response: For small brands or limited series, Fulcol offers low minimum order quantities and rapid sample production. The production process can be dynamically adjusted based on order volume, ensuring small batches enjoy high-quality standards and fast delivery.

- Customer Support and Feedback Loop: From order placement to delivery, customer feedback is promptly collected and incorporated into improvement systems. Fulcol optimizes processes, designs, or packaging based on client input, creating a closed-loop system for continuous improvement. Products not only meet original design standards but continually adapt to market and client needs.

Through full-process control, Fulcol achieves improvements in production efficiency, quality stability, and customer satisfaction, demonstrating its professional capability and authority in custom bracelet manufacturers and silver bracelet manufacturers industries.

| Start Your Custom Order | Email: info@fulcol.com | Number:+86-18876512305 |

In OEM silver jewelry production, plating thickness, solder joint strength, and stone setting quality are critical indicators. Through scientific testing, professional tools, 3D design application, and standardized processes, Fulcol ensures every 925 sterling silver bracelet and bangle reaches top industry standards.

For silver bracelet manufacturers and custom bracelet manufacturers, data-driven management, skill training, and closed-loop customer feedback are key to long-term quality stability and market competitiveness. Fulcol provides professional operations, flexible customization, and high-standard quality control, making it a trusted partner in the industry.