Table of contents

Jewelry Electrophoretic Coating and Its Principle

Definition and Concept

Electrophoretic coating (Electrophoretic Coating) is an advanced surface treatment technology that uses an electric field to make charged paint particles evenly deposit on the metal surface, forming a strong and uniform protective film. On custom 925 sterling silver jewelry, electrophoretic coating not only maintains the natural luster of silver but also enhances durability and overall texture, providing long-lasting protection for high-end jewelry.

Function of Electrophoretic Coating

- Protective function: The coating forms a barrier on the silver jewelry surface, blocking moisture, air, and daily chemicals (such as sweat, perfume, and cosmetics) from corroding the underlying metal, effectively delaying oxidation and corrosion.

- Extending lifespan: The protective film reduces the need for frequent cleaning and polishing, keeping the jewelry bright and new in daily wear.

- Wide applications: In addition to the jewelry industry, electrophoretic coating technology is also used in automotive parts, electronics, home appliances, aerospace, ships, and construction materials, demonstrating its reliability and versatility.

Comparison with Traditional Processes

- Electrophoretic coating: The jewelry is immersed in electrophoretic solution and electrified, allowing paint particles to deposit evenly, including complex chain links and carved details. The coating can be transparent or colored, glossy or matte, uniform and delicate, with strong adhesion and resistance to cracking.

- Electroplating: A thin metal film is deposited on the surface through electrical current, such as silver or gold plating. The appearance retains the metal’s natural color and texture, glossy or matte, but uneven thickness may lead to localized oxidation.

- Enamel: Glass powder is applied to the metal substrate and melted at high temperatures to form a surface that is colorful and smooth like glass. However, it is brittle and difficult to cover complex shapes.

Electrophoretic coating can achieve uniform coverage on complex structures of custom 925 sterling silver jewelry, providing rich gloss and color options, making it the preferred process for modern silver wholesale jewelry manufacturer producing high-end silver jewelry.

Function of Electrophoretic Coating

- Protect underlying metal: Electrophoretic coating forms a durable film on the jewelry surface, effectively preventing oxidation and corrosion, protecting silver jewelry from sweat, perfume, and chemicals during daily wear.

- Extend jewelry lifespan: The coating reduces wear caused by daily friction and chemical exposure, allowing the luster and texture of the jewelry to last longer.

- Enhance aesthetics: Transparent coating preserves the metal’s natural color, while colored coatings provide vibrant effects, meeting personalized customization needs.

- Lower maintenance cost: With the protective layer, jewelry requires less frequent cleaning and polishing, providing a convenient and worry-free wearing experience.

- Reliability proven across industries: This technology is widely used in automotive, electronics, home appliances, and aerospace, proving its durability and dependability.

Through these functions, electrophoretic coating not only improves jewelry durability but also enhances the added value of brand products in the market.

Electrophoretic Coating Process and Types

1. Standard Process Flow

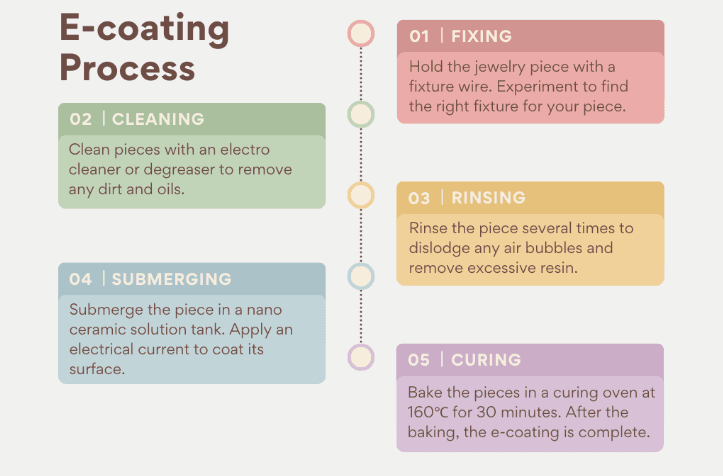

Electrophoretic coating is a key protective step in jewelry manufacturing, usually performed after polishing:

- Fixing jewelry components: Hang the jewelry on fixtures, ensuring parts do not touch other surfaces. For complex designs or stacked pieces, repeat the process to ensure every corner is evenly coated.

- Cleaning jewelry: Use electrolytic cleaners or degreasers to remove dirt, grease, or contaminants, ensuring uniform coating adhesion.

- Rinsing: Rinse multiple times with distilled water and running water to remove residual cleaning agents and prevent defects in the coating.

- Immersion in ceramic solution and electrification: Fully immerse the jewelry in nano-ceramic solution and apply current to evenly coat the surface.

- Curing the coating: After hanging to dry, place jewelry in a curing oven at 160°C for 30 minutes to harden the coating and enhance durability.

2. Coating Types

- Transparent electrophoretic coating: Maintains the natural luster of the metal and provides basic protection, suitable for silver and gold jewelry.

- Colored electrophoretic coating: Offers various colors such as blue, pink, red, and yellow, allowing personalized design and making jewelry visually striking.

3. Advantages of Jewelry Electrophoretic Coating

- High corrosion resistance and anti-tarnish: The coating blocks oxidation and corrosion, keeping jewelry bright and lasting.

- Coverage of complex structures: Ensures uniform protection for hollow, carved, and chain link areas.

- Smooth and uniform surface: Minimizes “orange peel” texture and enhances visual quality.

- Diverse colors and finishes: Glossy, matte, and colored options meet brand customization needs.

Fulcol’s Professional Advantages and Customization Capabilities

As a professional silver wholesale jewelry manufacturer, Fulcol provides high-quality custom 925 sterling silver and multi-material customized jewelry, offering end-to-end services from design to delivery, meeting global brand needs.

Rich Experience and Professional Team

Since its establishment in 2004, Fulcol has over 20 years of jewelry manufacturing experience, combining advanced equipment and exquisite craftsmanship to serve more than 1,200 brands. The design team specializes in trend research and 3D modeling, quickly turning concepts into production-ready models, while the technical team ensures the precision and quality of every piece.

Comprehensive Customization Capabilities

- Material selection: silver, brass, and premium plating finishes

- Finishes and colors: Glossy, matte, transparent, or colored electrophoretic coatings

- Brand identification: Custom engraving, logo stamping

- Packaging: Exclusive packaging and gift box design

This customization capability allows brands to fully control product details and achieve market differentiation.

Strict Quality Control and On-time Delivery

Every piece undergoes rigorous quality inspection to ensure durability, luster, and consistency meet international standards. With a 26,000 m² factory and a complete production process, Fulcol efficiently handles bulk orders. Combined with efficient logistics and on-time delivery, brands can focus on sales without production concerns.

Innovation and Sustainable Practices

Fulcol emphasizes design innovation while implementing sustainable production. Through eco-friendly plating, nickel-free and lead-free processes, and responsible material selection, each piece combines beauty with ethical standards. Trend-driven design and creative craftsmanship help brands create unique jewelry collections.

Durability and Common Questions of Electrophoretic Coated Jewelry

- How long does electrophoretic coated jewelry last?

Under proper conditions, with consistent materials and correct process execution, electrophoretic coating can extend the jewelry’s lifespan by approximately 2–3 months compared to uncoated pieces, effectively reducing oxidation and wear. - Will electrophoretic coated jewelry lose its luster?

Nano-ceramic particles give the coating anti-oxidation ability, keeping the jewelry shiny even with minor daily friction or chemical exposure. - Will electrophoretic coated jewelry wear off?

The coating is durable but not permanent; long-term use or frequent friction may gradually wear it down. Proper care, such as avoiding intense abrasion and chemical contact, can prolong the coating’s life.

| Start Your Custom Order | Email: info@fulcol.com | Number:+86-18876512305 |

Electrophoretic coating provides an efficient, uniform, and visually appealing protective layer for custom 925 sterling silver jewelry, making pieces more durable and long-lasting in daily wear. Combined with Fulcol’s professional customization capabilities and strict quality control, every piece achieves perfect realization from concept to final product. Whether transparent protective coating or colored personalized layer, electrophoretic coating offers a reliable, high-quality solution for modern silver wholesale jewelry manufacturer, allowing brands to confidently showcase unique design and craftsmanship value.