Table of contents

Common Surface Treatment Techniques for Silver Jewelry

Surface treatment techniques for silver jewelry not only affect visual appeal but also determine durability, oxidation resistance, and overall value. In professional custom manufacturing, common surface treatments include:

- Polishing: Polishing is a basic technique that removes minor surface imperfections through mechanical or manual grinding, producing a mirror-like finish. Fulcol combines automated polishing equipment with hand finishing to ensure uniform smoothness, enhancing both comfort and visual appeal. This technique is suitable for modern minimalist silver bracelets or necklaces.

- Electroplating: Electroplating enhances both the oxidation resistance and decorative effect of silver jewelry. Common coatings include rhodium, gold, and rose gold. Rhodium plating is highly durable, wear-resistant, and anti-tarnish, often used in high-end sterling silver custom jewelry. Fulcol can adjust plating thickness based on client requirements to balance aesthetics and durability.

- Brushing: Brushing creates fine linear textures, giving silver jewelry a soft metallic sheen and suitable for low-key or vintage designs. This process also effectively conceals minor scratches from daily wear, extending the jewelry’s lifespan. Fulcol strictly controls abrasive grit and brushing direction to ensure uniform texture.

- Sandblasting: Sandblasting sprays fine particles at high speed to produce a matte texture. It can be combined with polishing to create a “glossy-matte” contrast, adding visual depth and tactile appeal. Fulcol uses enclosed sandblasting chambers and precise controls to ensure uniform surface texture without residual particles.

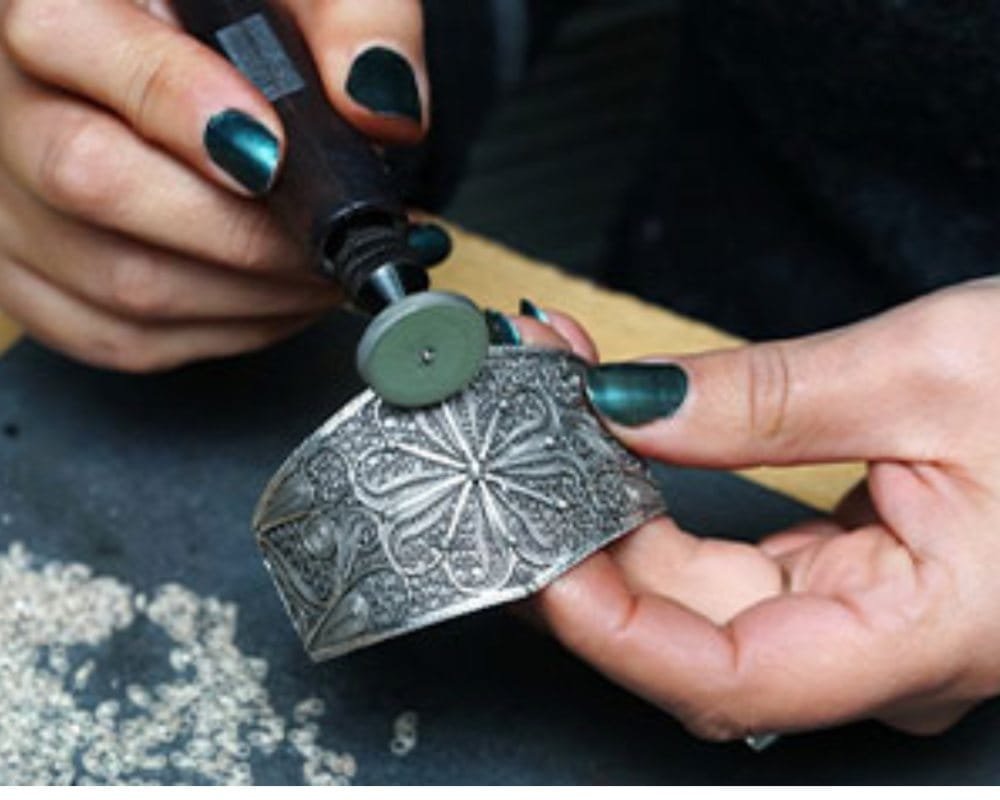

- Oxidation: Oxidation treatment produces variable surface shades on silver, commonly applied in vintage or artistic designs. Fulcol uses environmentally friendly oxidizing agents to ensure stable color while protecting the silver base, suitable for engraved, relief, or intricate textures.

- Laser Engraving: Laser engraving allows high-precision patterns or text, with accuracy up to 0.01 mm. Fulcol is equipped with imported laser engraving machines capable of carving brand logos, personalized designs, or relief details while keeping edges smooth.

Step-by-Step Guide for Silver Bracelet Surface Treatments

Surface treatment of silver bracelets is a systematic process involving multiple precise steps. The standard procedure includes:

- Preliminary Cleaning and Degreasing: Ultrasonic cleaning with a neutral detergent removes oil, dust, and impurities, ensuring a clean surface. Proper cleaning enhances adhesion for subsequent plating or polishing.

- Surface Pre-treatment: Includes grinding, edge trimming, and preliminary polishing to remove oxidation and minor scratches, ensuring a smooth surface. Fulcol conducts strict flatness checks for each bracelet to ensure uniform results.

- Fine Polishing: Coarse polishing adjusts the shape, while fine polishing produces a mirror-like finish. Fulcol combines automated polishing with hand finishing for uniform and natural luster.

- Texture Processing: Depending on design, brushing, sandblasting, or oxidation is applied to enhance dimension and tactile feel. Fulcol’s technical team recommends optimal finishes according to brand style.

- Electroplating: Plating with rhodium or gold improves oxidation resistance and surface shine. Fulcol ensures uniform plating thickness for long-lasting durability.

- Laser Engraving and Detail Work: Engraving logos or patterns requires high precision to maintain clarity and aesthetic quality.

- Final Cleaning and Protective Treatment: Ultrasonic cleaning followed by a protective anti-tarnish coating extends the jewelry’s shine retention.

- Quality Inspection and Packaging: Thickness of plating, wear resistance, and appearance are strictly inspected. Finished products are hand-polished and anti-tarnish packaged for shipment.

Fulcol’s Technical Advantages in Custom Sterling Silver Jewelry

Precision Manufacturing Combined with Hand Polishing: CNC cutting ensures highly accurate dimensions, while hand polishing guarantees uniform luster. Fulcol combines mechanical precision with handcraft quality, suitable for various custom silver bracelet manufacturer products.

- Nano Anti-Oxidation Plating Technology: Fulcol’s proprietary nano anti-oxidation plating forms a dense protective layer on silver surfaces, resisting sulfur and oxidation, reducing cleaning frequency, and prolonging shine.

- Environmentally Friendly Materials and International Standards: All polishing agents and plating solutions comply with RoHS and REACH standards, free of harmful elements, safe for skin, and meeting international high-end market requirements.

- High-Precision Laser Engraving: Imported laser equipment achieves 0.01 mm engraving accuracy. Combined with 3D texture techniques, Fulcol produces diverse surface effects such as hammered, matte, or relief finishes.

- Strict Plating Thickness and Wear Testing: Each piece undergoes plating thickness measurement and salt spray wear tests to ensure durability and aesthetic quality.

- Customization Technical Support: Fulcol provides full technical guidance, from design optimization to surface treatment planning, adjusting flexibly to meet small-batch or large-scale production needs.

How to Choose the Right Surface Finish for Silver Jewelry

Selecting the appropriate surface treatment requires evaluating design style, target market, budget, and maintenance needs.

- Based on design style

- For a modern, glossy look: recommend mirror polishing or rhodium plating.

- For a vintage style: oxidation or hand brushing offers more texture.

- To highlight dimensionality: use partial sandblasting combined with high polish.

- Based on wearing environment

- For daily wear, anti-oxidation plating reduces maintenance.

- For high-end displays or gifts, multilayer plating and mirror finishes enhance luxury appeal.

- Based on budget and positioning

- Thicker plating increases cost but extends durability.

- Brushing and sandblasting are more economical, suitable for mid-range mass production.

- Professional advice

- Brands should consult experienced silver bracelet manufacturer like Fulcol, letting engineers recommend the most suitable surface treatment according to design to avoid uneven shine or insufficient wear resistance.

Fulcol’s Customization Support for Brand Clients

- Full-Process Custom Services: Fulcol provides complete support from design consultation, 3D modeling, sample production, to mass manufacturing and quality inspection, ensuring on-time delivery.

- Rapid Prototyping and Flexible MOQ: Samples are typically completed in 7–10 days, with minimum order quantity as low as 50 pieces, facilitating market testing or limited edition production.

- Material and Surface Finish Optimization: Professional teams advise on material selection and surface treatment combinations to achieve optimal balance between aesthetics, durability, and cost.

- Quality Control and International Certification: All custom products undergo rigorous testing and can provide international standard reports (e.g., SGS, CE), helping brands meet global market requirements.

- Case Support and Brand Collaboration Experience: Fulcol offers reference cases and design guidance to help brands create high-end gifts, commemorative pieces, or limited edition sterling silver custom jewelry with artistic and commercial value.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

Custom sterling silver custom jewelry is not only an accessory but also a reflection of brand identity and artistry. Professional surface treatment enhances shine, texture, and durability. Fulcol leverages years of manufacturing experience, advanced technology, and full customization support to provide high-quality solutions for brands. From precision processing to meticulous polishing, from protective plating to personalized engraving, Fulcol ensures each piece is beautiful and durable, helping brands stand out in the market.