Table of contents

Understanding Wall Thickness of 925 Sterling Silver Rings

In jewelry design and manufacturing, the wall thickness of a ring is a crucial parameter that directly affects the ring’s durability, aesthetics, and wearing comfort. Wall thickness generally refers to the cross-sectional thickness of the metal part of the ring, especially in 925 sterling silver rings, commonly ranging from 1.0–2.5mm. Choosing the appropriate wall thickness not only ensures the ring does not deform or break during daily wear but also keeps gemstones securely set.

The importance of wall thickness can be summarized as follows:

- Structural stability: Rings with too thin walls are prone to bending or breaking under external forces. Especially for rings with intricate carvings or openwork designs, insufficient wall thickness significantly reduces overall structural strength, increasing the risk of after-sales repair.

- Gemstone security: Prong, bezel, or other setting methods rely on the metal’s load-bearing capacity. Too thin metal cannot support the prongs properly, making gemstones loose or even fall out.

- Wearing comfort and aesthetics: Excessively thick walls may increase the ring’s weight, affecting comfort, and make intricate details look bulky, which is not ideal for carved or hollow designs.

Recommended wall thickness :

- Classic plain rings: 1.5–2.0mm, ensuring structural stability while remaining comfortable.

- Openwork or intricately carved rings: 1.6–2.2mm in key stress areas, ensuring the ring does not break during daily wear.

- Inner band: Usually 1.2–1.5mm, balancing comfort with overall strength.

Following these recommended wall thickness values allows designers to maximize durability and gemstone security while maintaining aesthetic appeal.

Prong Setting Strength: Ensuring Gemstone Security

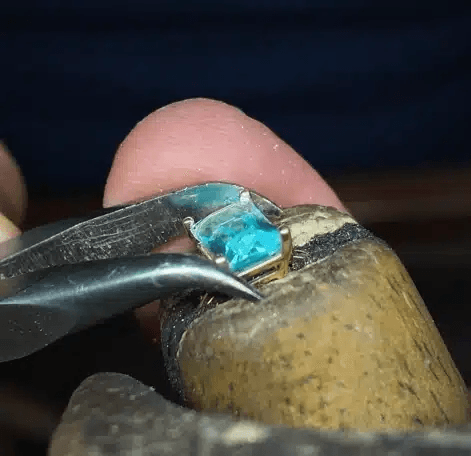

Prong setting is one of the most common gemstone setting methods, and its stability directly affects gemstone safety and wearing experience. Prongs typically hold the gemstone with 4 to 6 prongs, and the number, length, and angle of prongs influence stability and visual effect.

Key factors affecting prong strength include:

- Number and distribution of prongs: More prongs distribute force evenly, enhancing gemstone security, but too many prongs may obscure the gemstone. Round stones usually use 4 or 6 prongs, while oval or other shapes are adapted according to length and weight.

- Prong length and thickness: Too short or thin prongs reduce load-bearing capacity, making gemstones prone to loosening. For 925 sterling silver, prong thickness is usually recommended at 0.8–1.2mm, with length slightly above the gemstone tip by 0.5–1.0mm.

- Prong angle and curvature: The prong tip should bend slightly inward to fit the gemstone tip, ensuring security without damaging the gemstone.

- Material choice: 925 sterling silver has some toughness but is not as strong as platinum or palladium. For large or valuable gemstones, designers may use thicker prongs or internal reinforcement to ensure safety.

Following these recommended values significantly reduces the risk of gemstone loosening or falling while maintaining ring aesthetics.

Integrating DFM Principles into Ring Design

DFM (Design for Manufacturing) also applies to jewelry design. It emphasizes considering manufacturability and quality stability while ensuring aesthetic and creative designs. Applying DFM principles can effectively prevent common issues like insufficient wall thickness and unstable prong settings.

Steps to apply DFM in ring design:

- Start with CAD modeling: Use Rhino, MatrixGold, or ZBrush to create 3D models, precisely controlling wall thickness and prong positions.

- Simulate stress conditions: Use software to simulate potential stress directions and magnitudes during daily wear to identify weak points in advance.

- Optimize structural details: Adjust wall thickness distribution, prong angles, and ring curvature to ensure strength and aesthetics.

- Sample prototyping: Use 3D printing or wax models to verify wall thickness and prong stability before mass production.

- Assess manufacturing feasibility: Ensure the design fits the factory’s production capabilities, reducing polishing and finishing difficulties and improving efficiency.

By applying DFM, designers and manufacturers can avoid most potential issues during the design phase, improve ring quality, and reduce production costs and after-sales problems.

Fulcol’s Advantages and Practical Tips in Custom Sterling Silver Ring Manufacturing

As a professional sterling silver rings manufacturer, Fulcol has extensive experience and advanced technology in custom sterling silver ring production. Whether for small-batch custom orders or complex designs, Fulcol provides end-to-end solutions from design to manufacturing.

Fulcol’s manufacturing advantages and practical tips include:

- Wall thickness control: Precision molds and strict inspection ensure uniform wall thickness for every ring, which is critical for intricate carvings or openwork designs.

- Prong stability: Combining CAD simulation and manual adjustment ensures gemstones are securely set. For large or irregular stones, Fulcol optimizes prong thickness and angle based on stone weight and size.

- Sample prototyping: 3D printed or wax samples allow clients to verify wall thickness, prong security, and overall design before bulk production.

- Professional equipment and techniques: Microscopes check prong-to-gemstone contact to ensure a secure fit, while precision polishing tools prevent damage to wall thickness or prongs.

- Flexible small-batch customization: As a reliable silver rings factory, Fulcol supports fast response and small-batch production to meet personalized requirements.

These practices ensure structural stability, beauty, and maximize customer satisfaction, demonstrating the expertise of a professional sterling silver rings manufacturer.

Case Studies and Data Insights

To better understand the importance of wall thickness and prong strength, here are some practical cases and data analyses:

Case 1: Optimizing Wall Thickness for Intricate Carvings

- Original design wall thickness: 1.0mm. CAD simulation revealed local areas prone to breakage.

- Increased key stress areas to 1.6mm while keeping overall lightness; final sample passed wear testing without damage.

- Data support: Increasing wall thickness from 1.0mm to 1.6mm improved bending strength by approximately 45% (Source: Jewelry Material Mechanics Research, 2021).

Case 2: Adjusting Prong Height to Secure Gemstones

- A 2-carat round gemstone ring had slightly low prongs; minor impact caused stone loosening.

- Adjusted prong tips slightly inward and increased thickness to 1.1mm; gemstone remained secure under pressure testing.

- Data: Optimized design increased gemstone holding strength by approximately 35%, significantly reducing risk of detachment (Source: ISO 9208 Jewelry Testing Standards).

| Start Your Custom Order | Email: info@fulcol.com | Number:+86-18876512305 |

Wall thickness and prong strength play a decisive role in 925 sterling silver ring design. By applying DFM principles, scientific design, and precise manufacturing, designers and manufacturers can prevent structural issues, improve durability, and ensure gemstone security.

For custom jewelry, choosing an experienced sterling silver rings manufacturer and a reliable silver rings factory is crucial. Fulcol, with its professional skills, rich experience, and flexible customization capability, provides high-quality ring solutions, ensuring quality from design to production.

Mastering wall thickness control, prong design, and DFM methods not only enhances professionalism in jewelry pieces but also builds customer trust and satisfaction. Using CAD design, 3D prototyping, and microscope inspection allows theoretical knowledge to be converted into practical experience, making each ring beautiful, comfortable, and durable.