When you stop in front of the clean display cabinet and your eyes are attracted by the strings of sparkling K-gold jewelry, you may not know the ingenuity and science behind them. The reason why K-gold jewelry is popular in the current jewelry market is not only due to the sense of nobility brought by its gold color, but also due to the hardness and durability given by the alloy ratio, so that each piece can remain dazzling and withstand the test of daily wear.

As a gold jewelry manufacturers deeply engaged in the customization and wholesale fields, Fulcol has been focusing on the research and development and production of K-gold jewelry for more than ten years, from raw material selection to craftsmanship polishing, every step pursues precision and perfection. This article will take you to understand what K-gold jewelry is in a simple way: from the definition and classification of K-gold, manufacturing process, purchase points, to maintenance methods and misunderstandings, so that you can not only have professional knowledge reserves in addition to reading, but also be handy in actual operation, and confidently purchase and maintain your favorite works.

Table of contents

- What is K-gold jewelry?

- Composition and classification of K gold

- Manufacturing process of K gold jewelry

- Practical tips for choosing high-quality K-gold jewelry

- Fulcol——Advantages of Customization and Wholesale Manufacturer

- Tips for maintaining and caring for K gold jewelry

- Common misunderstandings and answers

What is K-gold jewelry?

K-gold, as the name implies, is an alloy metal that measures the purity of gold in units of “K” (Karat). 24K gold represents 100% pure gold, is soft in texture, and usually exists in the form of pure gold, which is difficult to be directly used in the production of complex jewelry. By melting 24K gold with copper, silver, zinc, palladium and other metals in proportion, it can not only maintain the original luster and dignity of the metal, but also greatly improve its hardness and wear resistance, thus obtaining a K-gold alloy suitable for daily wear.

When comparing the characteristics of pure gold, pure silver and K-gold, you will find that: although pure gold has high purity, it is too soft and easily deformed by external forces; pure silver is affordable, but it is easy to oxidize and turn black under the action of air or chemicals, and requires frequent cleaning and maintenance; while K-gold takes into account luster, hardness and plasticity, and is the preferred material for most modern jewelry brands.

More importantly, the “K number” of K-gold is not the higher the better. Different K numbers determine the color tendency, hardness level and price range of jewelry. Consumers and designers can flexibly choose the most suitable K gold type according to wearing needs, budget and style positioning.

Composition and classification of K gold

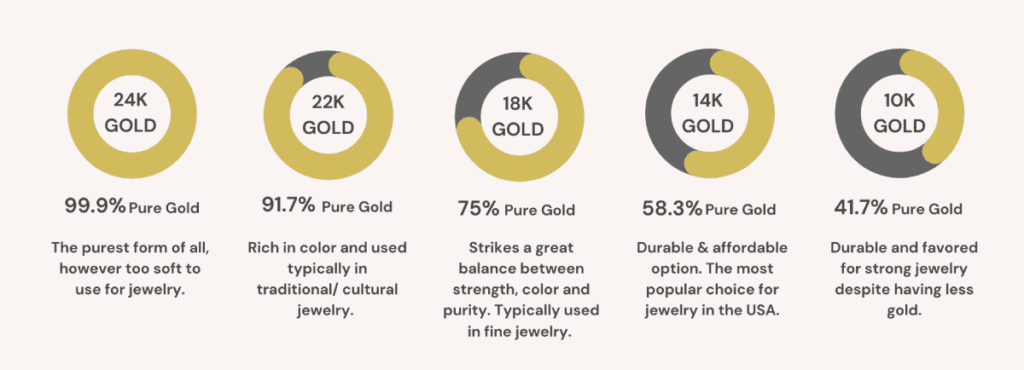

K number and gold content: balance dignity and durability

9K gold (37.5% pure gold)

It exchanges lower gold content for higher hardness and cost advantages, suitable for young groups or entry-level markets that pursue personalized design. Its appearance is white and practical, but it may fade slightly after wearing for a long time.

14K gold (58.3% pure gold)

It is the most common K gold material in Europe and the United States. It takes into account the saturation of gold and the toughness of metal, and the price is moderate. Whether it is a necklace, earrings, ring, or bracelet, 14K gold can present a golden luster that is neither too ostentatious nor loses texture.

18K gold (75% pure gold)

The luster of 18K gold is closest to pure gold, but the hardness is greatly improved. It is the main material for high-end customization and luxury brands. It has higher requirements for craftsmanship, and the difficulty and cost of processing are also increased accordingly.

24K gold (99.9% pure gold)

It usually only appears in the form of “pure gold”, such as 3D hard gold and traditional gold ornaments. It has a soft texture and is suitable for traditional hand-carving, but its application in modern precision jewelry is relatively limited.

The role and proportion secret of alloy metals

Copper (Cu)

It is one of the most common K gold alloy metals, which can give K gold a good ruddy color and hardness improvement. The higher the copper content, the more obvious the “rose gold” presented by the finished product.

Silver (Ag)

It is used in both yellow K gold and white K gold. Silver can make the alloy luster softer, without the red tone of pure copper, and it is also helpful to improve hardness and fluidity.

Zinc (Zn) and Nickel (Ni)

Mostly used in white gold to improve alloy homogeneity and improve the metal’s anti-allergic properties. But it should be noted that some people may have a sensitive reaction to nickel, so when producing white gold, many gold jewelry wholesale manufacturers prefer palladium (Pd) instead of nickel.

Palladium (Pd)

Belongs to the precious metal series. When combined with gold, it can make white gold whiter and naturally anti-allergic, but the cost is high and usually appears in mid-to-high-end white gold products.

K gold color evolution – the secret of a thousand-faceted metal

Classic yellow gold

Closest to natural gold, it is a mixture of gold and alloy metals such as silver and zinc, presenting a warm but not dazzling golden color, which is a timeless classic in jewelry design.

Shining white gold

In order to be closer to the silvery white luster of platinum, white gold is often electroplated with rhodium (Rhodium), giving the surface a bright white effect and increasing wear resistance. The rhodium layer will slowly wear out over time and needs to be re-plated regularly to maintain the best appearance.

Romantic rose gold

Due to the increased copper content, it presents a soft pink gold tone, which is deeply favored by young consumers and the fashion circle. Rose gold can not only blend with various skin tones, but is also very suitable as a material choice for couples’ rings and commemorative jewelry.

Manufacturing process of K gold jewelry

Raw material selection and smelting process

In Fulcol’s production workshop, material selection is particularly critical. We strictly control the weight ratio of 24K gold and various alloy metals. Each batch of raw materials must pass chromatographic analysis and trace element detection to ensure accurate ratio. The prepared metal is placed in an induction high-frequency furnace. After vacuum degassing, the liquid alloy has higher uniformity and fewer impurities. Finally, it is poured into a pre-heated mold and cooled to form a K gold blank.

Casting, stamping and 3D printing: a model of multi-process integration

Traditional lost wax casting:

The designer makes a wax mold based on 3D modeling. After sandblasting and curing, the wax mold is placed in ceramic sand. After the wax core is burned off at high temperature, the molten K gold alloy is injected into the ceramic sand mold cavity. This process can retain complex textures and fine structures to the greatest extent, and is the first choice for high-end customization.

Stamping:

The K gold sheet is formed in the mold by a high-speed stamping machine. It is suitable for simple styles and mass production. It is low-cost and high-efficiency, but it has restrictions on the complexity of the structure.

Precious metal 3D printing:

Using metal powder bed melting or laser melting technology, the 3D model is directly “printed” layer by layer, which can achieve extremely fine structures and bold and avant-garde designs. It is especially suitable for conceptual and limited precision jewelry production.

Fine grinding and surface treatment

The formed blank needs to go through multiple grinding processes, using sandpaper, polishing wheels and professional polishing paste to gradually remove surface defects until it is as smooth as a mirror. Then the electroplating process is carried out: white K gold needs to be rhodium-plated, and pink gold may be electroplated at the micron level to stabilize the copper element and make it less prone to oxidation. Finally, the gem setting is completed according to the design requirements to ensure that each diamond or gem is firmly placed, and the final quality inspection is carried out.

Practical tips for choosing high-quality K-gold jewelry

Step 1: Carefully check the K-number mark and purity certificate

When choosing K-gold jewelry, be sure to find the “KXX” mark on the inner ring of the ring, earrings or the top of the pendant, and ask the gold jewelry wholesale manufacturer for a national or internationally certified gold content inspection certificate, such as NGTC (Jewelry and Jade Quality Inspection Center of the Chinese Academy of Geological Sciences) or GIA (Gemological Institute of America) report, to ensure that every gram of gold you buy has a real endorsement.

Step 2: Actual experience of touch and color

Different K-golds have obvious differences in feel and color:

- Yellow K-gold should have a warm golden luster and a slight sense of temperature when touched.

- White K-gold should be crystal clear, without impurities, and have a smooth surface.

- Rose gold has a soft pink gold tone and a warm color system, which is particularly harmonious when combined with the skin.

If conditions permit, try on different styles and observe them from multiple angles under natural light and indoor light sources to ensure stable and uniform color.

Step 3: Pay attention to after-sales and warranty services

Excellent gold jewelry manufacturers and wholesalers usually provide:

- Lifetime free cleaning and polishing to keep your jewelry new.

- Rhodium plating or refurbishment services to extend the luster of white gold or rose gold.

- Inlay inspection and repair, regularly check the firmness of gemstones to prevent them from falling off during wearing.

Before placing an order, you should consult the customer service in detail about the service cycle, cost and process to avoid inconvenience in future maintenance.

Recommended practical tools

Gold test pen: Based on the principle of chemical reaction, it can determine the surface alloy color tone within seconds, which is suitable for ordinary consumers to make preliminary identification.

Portable XRF metal analyzer: Although the price is relatively high, it can achieve non-destructive testing and multi-element analysis, and is the preferred equipment for jewelers and professional factory inspectors.

Magnifying glass and inspection light: When checking the details of jewelry, the magnifying glass can help you observe the engraving, welding points and gemstone inlay details, and the inspection light can show surface scratches and coating uniformity.

Fulcol——Advantages of Customization and Wholesale Manufacturer

First-class Production Strength and Experience

Fulcol brings together a team of top craftsmen, jewelry designers and engineers, equipped with internationally leading precious metal smelting furnaces, precision CNC casting equipment and 3D printers, and has provided customization and wholesale services for more than 100 jewelry brands around the world. We are well aware of market trends and consumer psychology, and can quickly transform creative concepts into high-quality finished products.

Complete and transparent customization process

Demand matching: From brand positioning, target groups to budget range, professional account managers follow up throughout the process and provide a draft of the design plan.

3D design and sample confirmation: Quickly make samples through CAD software and 3D printing, invite customers to review the physical objects, and modify them repeatedly until they are satisfied.

Small batch trial production: Invest in a small amount of production to verify the process and ensure consistent quality during mass production.

Large-scale production and quality inspection: Carry out mass manufacturing according to customer requirements, implement a quality inspection system that combines full inspection, sampling inspection and random re-inspection, and all finished products are accompanied by factory quality inspection reports.

Packaging and logistics: Provide customized gift boxes, certificates and packaging accessories according to brand needs, and cooperate with international logistics partners to ensure safe and timely delivery of goods.

Flexible advantages of wholesale cooperation

Flexible minimum order quantity (MOQ): meet the diverse needs of emerging brands and small-volume markets;

Stable supply and short delivery time: fast delivery is achieved with automated production lines and complete raw material reserves.

Transparent prices and cost advantages: strive for maximum profit margins for customers through large-scale procurement and refined production cost control.

Professional one-to-one service: From product development to after-sales maintenance, Fulcol always grows with you as a partner.

Tips for maintaining and caring for K gold jewelry

Daily cleaning and simple care

Warm water and neutral detergent: After soaking the jewelry for 5-10 minutes, use a soft-bristled toothbrush to gently scrub the fine seams, finally rinse with clean water and wipe dry with a microfiber cloth.

Ultrasonic cleaning: For complex jewelry with more gemstones, ultrasonic deep cleaning can be performed every six months or according to the frequency of wearing.

Avoid contact with chemicals: cosmetics, perfumes, and chlorine-containing cleaners will accelerate the oxidation of the K gold surface or the shedding of the rhodium layer. It is recommended to take off the jewelry before using such products.

Prevent wear and deformation

Partition storage: Put the jewelry in a separate jewelry box or soft velvet bag to avoid friction between metals or other hard objects.

Avoid strenuous exercise: When doing strenuous exercise or housework, you should take off the jewelry to prevent impact or concentrated force from causing deformation.

Regular polishing and refurbishment: According to the frequency of wearing, send it to a professional organization for polishing and electroplating every year or every two years to make the K gold jewelry shine again.

Common misunderstandings and answers

Misunderstanding 1: “The higher the K number, the better”

Truth analysis: Although the higher the K number, the higher the gold content and the higher the wearing value, 24K gold is too soft, easy to scratch and difficult to maintain its shape. 18K gold is the first choice of most high-end brands. It has both sufficient gold content and excellent hardness.

Myth 2: “White K gold itself is silvery white”

Truth analysis: Pure white K gold has a slight yellowish tint, and generally needs to be electroplated with rhodium to achieve a pure white appearance like platinum. The rhodium layer will gradually wear out with daily wear, and when it turns slightly yellow, it can be sent to a professional store for re-plating.

Myth 3: “Customized jewelry is overpriced and is being ripped off”

Truth analysis: The price structure of customized jewelry includes design fees, raw material fees, process fees and labor costs. Each piece is a one-to-one service, and the cost cannot be diluted through large-scale mass production. Choosing a regular gold jewelry manufacturer can ensure that the craftsmanship and quality are improved simultaneously, and the cost-effectiveness is higher.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

Correct material recognition and exquisite process flow are the key to ensuring the long-term brilliance of jewelry. The scientific and convenient purchase and maintenance methods can make you confident and worry-free during the wearing process. As a trustworthy gold jewelry wholesale manufacturer, Fulcol will continue to provide high-quality customization and wholesale services to every consumer and brand partner with professionalism and innovation. Now, let us start the K gold journey together and let every bit of brilliance become a witness to your unique identity.