Table of contents

Understanding the Core Role of CAD in Custom Brass Jewelry Design

Definition and Application of CAD in Jewelry Design

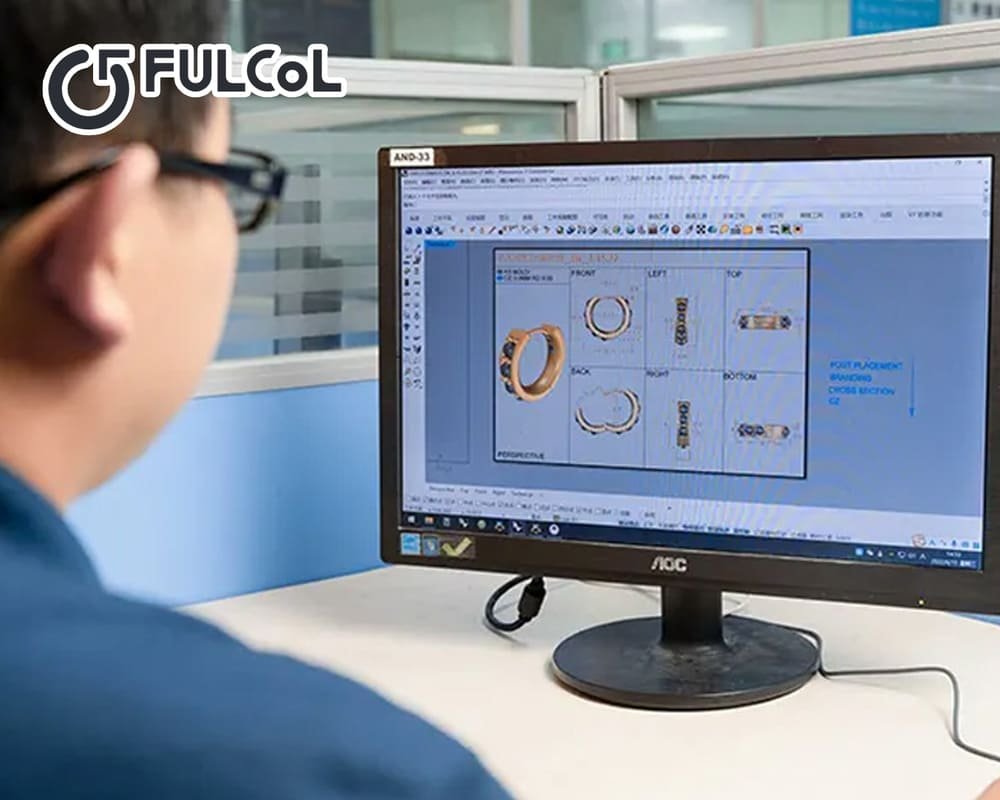

Computer-Aided Design (CAD) plays a crucial role in modern custom brass jewelry design. It allows designers to digitize their creative ideas, verify proportions, structures, and functionality in a virtual environment, and reduce the cost of creating physical prototypes. With CAD, designers can quickly generate design models and communicate with clients online, improving design efficiency and customer satisfaction.

Main Functions

- 3D Modeling: Create complex three-dimensional structures, including rings, pendants, bracelets, and intricate openwork patterns.

- Parametric Design: Automatically updates related elements when dimensions or proportions change, ensuring overall design consistency.

- Virtual Rendering: Produces realistic material and shine effects for online client previews and approvals.

- Dimensional Accuracy Control: Ensures precise placement of insets, clasps, and curves, providing reliable data for production.

Common Software Tools

- RhinoGold: Specifically designed for jewelry, supporting modeling and rendering.

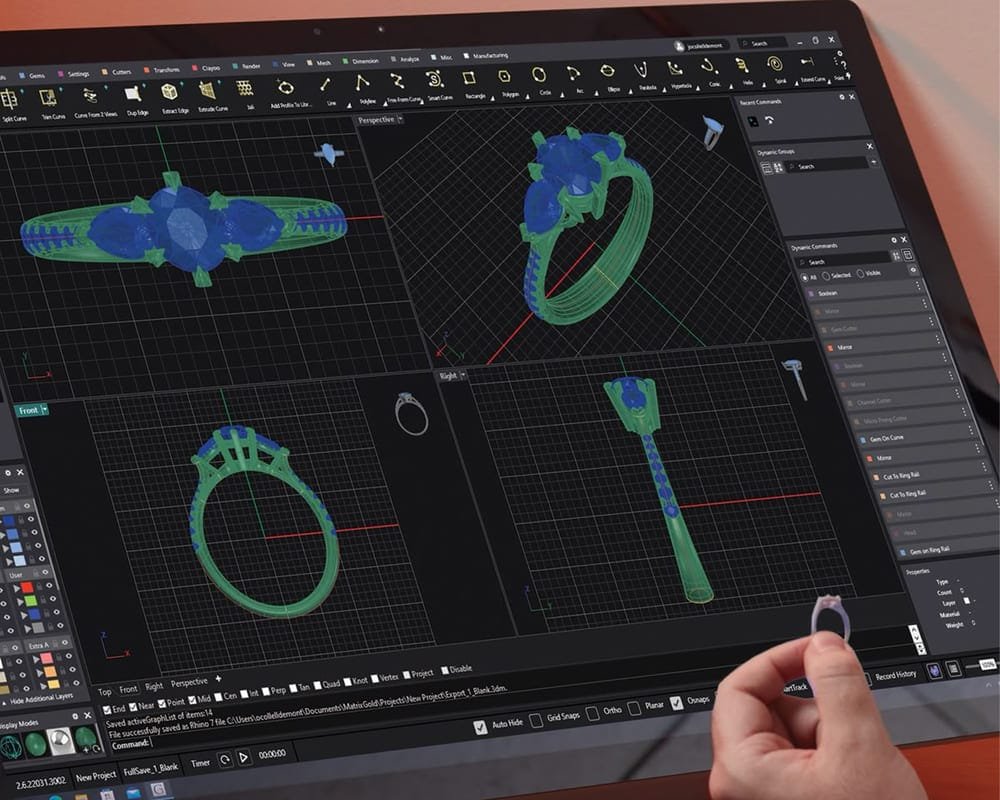

- MatrixGold: Powerful tool suitable for complex brass pieces.

- AutoCAD: Technical drawing software ideal for precise measurements.

- Blender: Open-source modeling and rendering software, suitable for creative experiments and complex shapes.

Case Example

When designing a custom brass ring, designers can quickly generate multiple 3D model options using CAD and provide rendered images for client selection and modification. This approach reduces the cost of physical prototypes and speeds up communication and approval.

The Value of CAM in Turning Designs into Reality

Definition and Basic Workflow of CAM

Computer-Aided Manufacturing (CAM) transforms CAD designs into physical products, including:

- CNC Milling/Routing: Precisely cutting wax models or metal blanks.

- Casting Preparation: Creating molds for lost-wax casting while preserving design details.

- Laser Engraving and Cutting: Produces high-precision textures and patterns that are difficult to achieve manually.

Advantages of CAM in Brass Jewelry Manufacturing

- High Precision: Ensures every detail of complex structures is accurately reproduced.

- Repeatability: Identical designs can be produced in batches with consistent quality.

- Material Efficiency: Optimized tool paths reduce brass waste.

Practical Applications

- CNC machining can produce wax models or metal blanks directly from CAD files.

- 3D printing is used for rapid prototypes to verify design feasibility and client review.

- Laser engraving adds fine textures or brand markings, increasing product value.

Deployment in a Custom Brass Jewelry Manufacturer

Professional factories integrate CAM with traditional craftsmanship. Machines handle precision cutting and engraving, while artisans polish, set stones, and perform surface finishing. This combination ensures every piece of custom brass jewelry meets high-quality standards.

Essential CAD/CAM Tools and Software for Jewelry Designers and Manufacturers

CAD Software Recommendations

- RhinoGold: Comprehensive professional features at moderate cost, suitable for jewelry designers.

- MatrixGold: Excellent for highly customized production, powerful but requires learning.

- AutoCAD: Focused on technical drawing and dimensional accuracy.

- Blender: Free, open-source, rich functionality, requires modeling experience.

CAM Tools and Equipment

- CNC Machines: For wax model or metal blank processing, ensuring precise details.

- Casting Equipment: Used for lost-wax casting of brass jewelry.

- Laser Engraving Machines: For fine texture and brand engraving.

Integrated Software and Plugins

- Tools like Gemvision Matrix and ZBrush improve CAD/CAM integration and reduce file conversion errors.

- ZBrush enhances sculpting and artistic expression, making complex designs feasible.

Cloud Collaboration and Remote Customization

Cloud-based CAD/CAM platforms allow designers and factories to share files in real-time, while clients can review and suggest modifications online. This improves communication efficiency and production flexibility, becoming a key trend for modern Custom Brass Jewelry Manufacturers.

From CAD to Finished Product: Workflow of Brass Jewelry Manufacturing

- Conceptual Sketching: Designers start with hand-drawn or digital sketches, turning ideas into visual concepts. This stage focuses on overall form, proportion, and functionality, providing clear references for CAD modeling and facilitating initial client communication.

- CAD Modeling and Rendering: Sketches are converted into precise 3D models, and virtual rendering simulates brass material and shine. Designers check curves, insets, and structural proportions to ensure accuracy, while clients can review models online and suggest changes, improving customization efficiency.

- CAM Processing and Wax Model Printing: CAD files are processed through CAM software to generate CNC toolpaths or 3D printing instructions for wax models or rapid prototypes. This step verifies design feasibility and identifies potential manufacturing issues, ensuring smooth transition to casting. Digital processing combined with traditional craftsmanship enhances efficiency and reduces errors.

- Brass Casting and Post-Processing: Wax models are used for lost-wax casting, transforming the design into brass pieces. Castings undergo grinding, deburring, and refinement to ensure detail integrity. Each piece is thoroughly inspected for structural strength and dimensional accuracy, preparing for polishing and surface finishing.

- Polishing, Plating, and Quality Inspection: Finished castings are polished to enhance shine and tactile quality. Electroplating can add durability or provide gold-toned finishes. Finally, each piece of custom brass jewelry undergoes comprehensive quality checks, ensuring size, texture, and stone setting meet standards, reflecting meticulous craftsmanship.

FAQ and Professional Recommendations

Q: Which is better for custom brass jewelry, CAD or handcrafting?

A: CAD excels at complex structures and precision control, while handcrafting enhances artistic expression. The ideal approach combines CAD for modeling and verification with handcrafting for detailed sculpting and polishing, achieving both accuracy and artistry.

Q: How to ensure dimensional accuracy and comfort?

A: Designers should control ring sizes, bracelet lengths, and clasp dimensions in CAD. CAM processing ensures wax models and castings meet design requirements. Polishing and surface finishing maintain appropriate thickness for comfortable wear.

Q: How to ensure durability and oxidation resistance?

A: Use high-quality brass and apply polishing, plating, or protective coatings to improve wear and oxidation resistance. Regular cleaning and proper use further extend lifespan.

Q: What is the typical production lead time? Is small-batch customization supported?

A: Modern Custom Brass Jewelry Manufacturers can rapidly produce wax models or prototypes, with small-batch custom orders typically completed within weeks. CAD/CAM technology increases production flexibility, efficiently handling small, diverse orders.

Q: How to choose the right manufacturer?

A: Consider whether the manufacturer integrates CAD/CAM with craftsmanship, has an experienced team, offers rapid prototyping, and maintains a complete quality inspection system. A good manufacturer not only produces according to design but also provides professional advice to optimize final results.

Professional Recommendations

- Maintain quality control at every step to ensure each piece of custom brass jewelry meets high standards.

- Communicate design details thoroughly in the early stage to reduce revisions.

- Use CAD/CAM rationally: machines handle complex structures, hands refine sculpting and polishing.

- Select suitable materials and surface treatments for aesthetics, durability, and comfort.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

CAD and CAM technologies are indispensable in modern custom brass jewelry design and manufacturing. They enable designers to realize complex creative ideas, allow manufacturers to produce high-quality products efficiently and accurately, and ensure every piece maintains consistency and artistry. By integrating digital tools with traditional craftsmanship, modern Custom Brass Jewelry Manufacturers can provide high-quality, personalized brass jewelry and drive sustainable industry development.