Table of contents

Lost-Wax Casting Basics: Understanding Core Principles

Lost-wax casting is a time-honored and precise metalworking technique, widely used in jewelry, sculpture, and industrial components. Its core principle is creating metal pieces using a wax model. The key points are as follows:

Principle Overview

Designers first carve the jewelry shape in wax, then encase the wax model in a heat-resistant investment material. After hardening, the wax is melted out to create a cavity, and molten brass is poured into the cavity to form the final piece. This process allows complex designs and fine details to be perfectly transferred to metal jewelry.

Advantages in Brass Jewelry

- High-detail reproduction: capable of intricate textures, hollow designs, and engravings.

- Strong repeatability: suitable for small-batch custom pieces as well as larger production runs.

- High design freedom: minimal limitations compared to traditional mechanical methods, enabling creative designs.

History and Modern Applications

Lost-wax casting has a history of several thousand years, tracing back to ancient Egypt and Mesopotamia. In modern jewelry production, combining digital modeling, 3D-printed wax models, and advanced casting materials allows precision to reach micrometer levels, meeting the needs of today’s Custom Brass Jewelry Manufacturer for complex brass jewelry.

Environmental and Economic Efficiency

The process reduces material waste while maintaining high precision and production efficiency, making it both economically and environmentally friendly for custom and batch production.

Step-by-Step Lost-Wax Casting Process

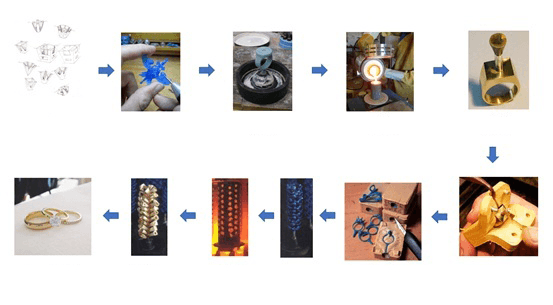

- Preliminary Design and Modeling: Design is the first step and crucial for accuracy and aesthetics. Designers usually create sketches or digital models using software like Rhino, Matrix, or CAD. Considerations include uniform wall thickness, proper sprue design, and avoiding fragile sharp points. For complex designs, digital modeling can simulate casting results, reducing trial-and-error costs.

- Wax Model Creation: The wax model is the core of lost-wax casting, made from high-melting-point wax, injection wax, or sculpting wax. Hand-carved wax suits unique designs, while injection wax is suitable for batch production. Detail precision directly impacts the final cast. Wax models are often connected in a sprue tree for easier metal pouring.

- Investment Pouring: The wax model is encased in a high-temperature-resistant investment material, typically plaster, silica, or high-temperature resin. The material must fully cover the wax without bubbles or gaps. Once hardened, it forms a sturdy mold for burnout and metal casting.

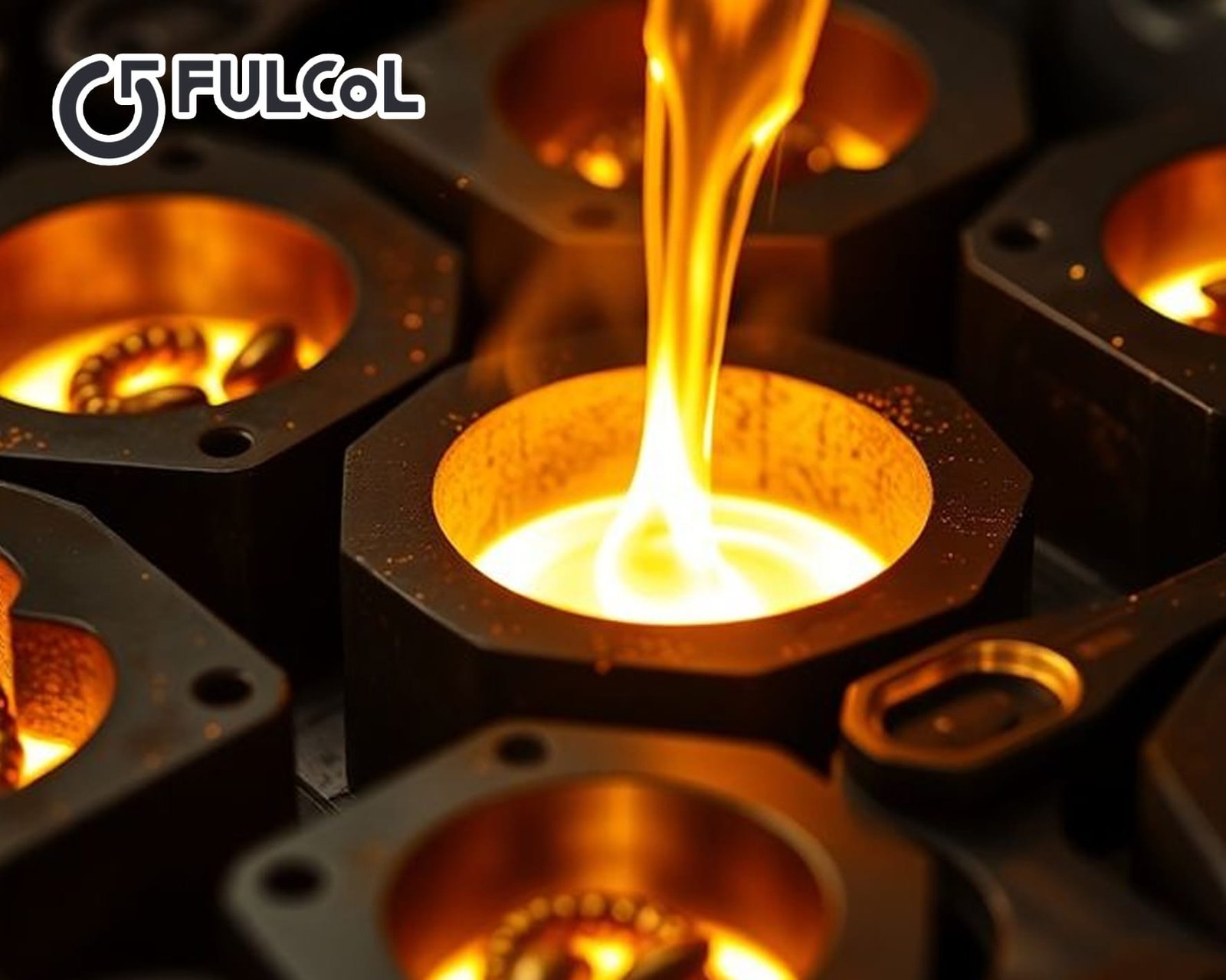

- Wax Burnout and Casting: The hardened mold is heated in a furnace, melting the wax to leave a precise cavity. Molten brass is then poured via centrifugal, gravity, or vacuum casting. Temperature and pouring speed must be carefully controlled to avoid air pockets, cracks, or shrinkage.

- Cooling, Demolding, and Finishing: After cooling, the mold is broken to remove the casting. Residual sprues and excess metal are cut off, followed by grinding, polishing, and fine detail repair. Proper finishing enhances the jewelry’s texture, ensuring every brass piece meets high standards for both custom and batch orders.

Common Tools and Materials for Brass Jewelry Casting

Tool and material selection directly affects quality and efficiency in brass lost-wax casting:

- Furnaces: High-temperature casting furnaces, centrifugal casting machines, or vacuum casting machines, ensuring stable brass melt temperatures (approx. 900–950°C) and minimizing oxidation.

- Wax Tools: Carving knives, micro chisels, and engraving molds to achieve intricate textures.

- Investment Materials: Heat-resistant plaster, casting resin, or silica capable of withstanding 950°C without cracking.

- Brass Materials: Standard brass alloy with 60–70% Cu and 30–40% Zn, offering moderate hardness and good polishability.

- Finishing Tools: Sandpaper, polishing machines, vibratory tumblers, and plating equipment for defect removal and surface shine.

Practical Tips:

- Apply a mold release agent to the wax model to reduce air pockets.

- Design sprue trees properly to ensure smooth metal flow and reduce shrinkage.

- Vacuum casting reduces oxidation and increases yield.

- Remove impurities from molten brass for consistent color and texture.

With proper tools and material choices, even small-batch custom jewelry can achieve high precision and aesthetic appeal.

Quality Control and Post-Processing Techniques

High-quality brass jewelry relies not only on precise casting but also on strict quality control and post-processing:

Surface Grinding and Polishing

- Grinding: Use progressively finer sandpapers (#240 → #1000) to remove casting residues and defects.

- Polishing: Use polishing compounds and vibratory tumblers to enhance metal shine, meeting standards for custom or batch orders.

Detail Inspection

- Use magnifying glasses or microscopes to inspect textures, engravings, and hollow details.

- Check dimensions and weight; industry tolerances are typically ±0.1–0.3 mm, with weight deviations ±2–3%.

Anti-Oxidation Treatment

- Apply plating, wax, or coatings to protect surfaces and extend jewelry lifespan.

- For wholesale orders, uniform protection ensures consistent appearance.

Through rigorous quality control, every piece achieves design intent and meets client expectations for both Custom Brass Jewelry Manufacturer and wholesale brass jewelry standards.

Fulcol’s Casting Expertise: Why Choose an Experienced Manufacturer

Fulcol, as a professional Custom Brass Jewelry Manufacturer, has years of experience and technical expertise in brass lost-wax casting. Key advantages include:

- Rich Experience and Technical Knowledge: Fulcol has mature casting workflows capable of handling designs from simple to intricate hollow patterns. The professional team manages every step, from wax model creation and investment selection to burnout and casting temperature control, ensuring high-precision design reproduction.

- Precision Casting Process: High-precision casting reproduces textures, engravings, and complex structures while minimizing air pockets, shrinkage, and cracks. Even small-batch custom orders maintain the same detail quality as large-scale production.

- Strict Quality Control: Every casting undergoes multi-stage inspection, including size, weight, tolerance, and surface texture checks. Modern tools, such as microscopes, detect minor defects, ensuring flawless results.

- Flexible Custom and Wholesale Services: Fulcol supports small-batch customization and wholesale brass jewelry orders, offering short production cycles and flexible delivery. Clients can adjust designs or material selections while enjoying reasonable costs and consistent quality.

- Design Optimization Advice: Fulcol not only manufactures but also provides design optimization guidance, balancing castability and aesthetics to realize creative and functional jewelry designs.

Partnering with Fulcol guarantees high-quality brass jewelry, innovative design realization, production efficiency, and reliable delivery—core reasons it is a trusted Custom Brass Jewelry Manufacturer.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

Lost-wax casting provides unparalleled freedom and precision in brass jewelry design and production, allowing complex creations to be perfectly realized. From initial design to final polishing, every step is crucial, with tools, material quality, and process control directly determining the final product.

Choosing an experienced Custom Brass Jewelry Manufacturer, such as Fulcol, ensures precise details, stable quality, and efficient delivery for small-batch custom or wholesale brass jewelry orders. Whether for personal customization or brand wholesale, combining lost-wax casting with a professional manufacturer transforms creative ideas into reality while maintaining cost efficiency and environmental responsibility.

By understanding lost-wax casting principles, workflow, and quality control, designers and jewelry enthusiasts can confidently achieve custom brass jewelry that showcases unique craftsmanship and exceptional detail.