In the dazzling world of jewelry, gemstone rings always play a dazzling role – it symbolizes love, identity and personality, and is an important item for people to express their feelings at special moments. But have you ever wondered how these works of art that shine on your fingertips transform from a piece of ordinary metal and a loose stone to a stunning custom jewelry? What kind of complex and exquisite process is hidden behind it?

Fulcol gemstone jewelry manufacturers will take you to explore the entire process of gemstone rings from design to delivery, revealing how professional custom ring manufacturers and experienced gemstone jewelry manufacturers turn creativity into reality. Whether you are a consumer who is curious about jewelry customization or a jewelry wholesaler who is looking for a high-quality partner, we will provide you with useful help.

Are you ready? Now let’s start this wonderful journey of jewelry from the first step – design.

Table of contents

- Design and 3D modeling: the first step from creativity to reality

- Prototype design/sampling: “feeling” the design

- Rings and chains: metal craftsmanship determines the basic quality

- Gemstone selection and cutting: the art of giving soul to the ring

- Gemstone setting: the precise art of holding the gemstone firmly

- Quality inspection and refinement: Every detail cannot be compromised

- Finished product cleaning and packaging: Delivering quality to customers

Design and 3D modeling: the first step from creativity to reality

The manufacturing journey of each gemstone ring begins with an idea. This idea may come from the customer’s personal expression, a symbol of emotion, or inspiration from a popular trend. For professional custom ring manufacturers, design is not as simple as drawing a picture, it is also a process of visualizing emotions and scientifically structuring.

Communicating needs with customers

The first step of customization is to deeply understand the customer’s wishes and preferences. This may include the following aspects:

- The desired metal material (such as 925 sterling silver, 14K gold, 18K gold, brass, etc.)

- The type and color of gemstones (for example, ruby represents passion, sapphire symbolizes loyalty)

- Style (modern simplicity, retro luxury, ethnic style, personality trend)

- Ring size and purpose (engagement, wedding, birthday gift, daily wear)

Experienced jewelry designers usually guide customers to express their needs and provide design suggestions to help customers gradually clarify vague ideas.

Sketches and hand-drawn designs

After the customer’s needs are clear, the designer will first use hand-drawn sketches to quickly outline the general shape of the ring. This step emphasizes creative expression and aims to have a preliminary visual communication with the customer.

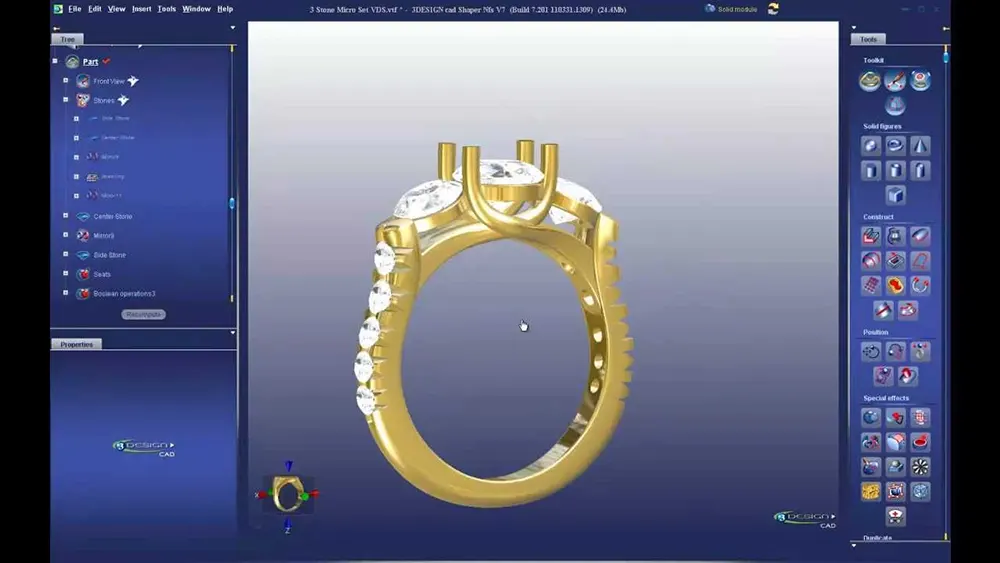

3D Modeling with CAD

After the sketch is confirmed, the designer will use CAD (computer-aided design) software such as Rhinoceros, MatrixGold, ZBrush, etc. for detailed modeling. The advantages of CAD modeling are:

- It can accurately control the parameters such as the size of the ring, the gem setting, and the thickness of the structure.

- Through virtual rendering, customers can preview the finished effect, such as metal color, gloss, and inlay method.

- Provide digital support for subsequent 3D printing or wax model making.

This technology transforms creativity into a quantifiable and achievable structural model, which is an indispensable part of the modern jewelry manufacturing process.

Prototype design/sampling: “feeling” the design

After the CAD modeling is completed and confirmed by the customer, the next step is to make a prototype, also known as “proofing”. This stage is a key step from the digital world to the physical reality. It allows designers and customers to discover the shortcomings of the design in advance and adjust them to ensure perfection before mass production.

3D printed wax or resin mold

Modern jewelry manufacturers generally use 3D printing technology to print prototype models, and common materials include wax or resin. 3D printing has the advantages of high precision and high restoration, and can be used directly for lost wax casting.

Hand-made wax carving (traditional method)

For high-end jewelry that requires extremely high artistry or limited customization, some manufacturers still insist on using hand-made wax carving technology, and experienced technicians hand-carve the shape of the ring, which is more humanistic and artistic.

Prototype detection and wearing test

After the proofing is completed, the prototype ring will be handed over to the quality inspector or the customer for trial wearing to evaluate whether the size is appropriate, whether it is comfortable to wear, and whether there are safety hazards such as sharp corners and gaps. This stage can also be fine-tuned according to customer feedback.

After the prototype is confirmed, the formal production stage can be entered, that is, mold making and metal casting.

Rings and chains: metal craftsmanship determines the basic quality

The core structure of the gemstone ring is made of metal, which not only determines the overall stability and appearance style of the ring, but also is a solid base for carrying gemstones. For gemstone jewelry manufacturers, choosing high-quality metals and precise craftsmanship is crucial.

Mold making and metal casting

Metal making usually adopts the “lost wax casting” technology:

- Wrap the wax mold with plaster, and burn off the wax at high temperature after the plaster dries to form a mold cavity.

- Pour the molten metal into the mold cavity, knock off the plaster after cooling, and get the rough embryo.

- The rough embryo is cleaned and polished before entering the next stage.

Molding metals include:

- 925 sterling silver: cost-effective, suitable for fashion jewelry

- K gold (14K/18K): moderate hardness and good wear resistance

- Brass or copper alloy: used for bulk wholesale orders, with good plasticity

Welding and chain connection

If the design includes a chain or a complex structure (such as a ring with a pendant), multiple parts need to be connected by precision welding. After welding, re-polishing is required to restore the overall finish.

Polishing and surface treatment

Polishing can be subdivided into initial grinding, fine grinding and mirror polishing to ensure that every inch of the metal surface is smooth and flawless. Some customizations will also add special treatments:

- Platinum/rhodium plating: enhance the luster and anti-oxidation ability of silver jewelry

- Aging craftsmanship: create a retro style

- Engraved texture: highlight design details

This stage determines the overall look and feel of the ring and the wearing experience, and is an important transition from “embryo” to “finished product”.

Gemstone selection and cutting: the art of giving soul to the ring

Metal is the foundation, and gemstone is the soul of the ring. The selection, cutting and processing of gemstones will directly affect the visual effect, value and emotional expression of the finished product.

Select high-quality gemstone raw materials

Professional gemstone jewelry manufacturers usually cooperate with stable gemstone suppliers for a long time to ensure that the source of gemstones is legal and the quality is controllable. When purchasing gemstone raw materials, the following factors need to be considered comprehensively:

- Color: whether it is pure, rich, and with or without color bands

- Clarity: whether there are inclusions, impurities or cracks

- Cut: whether the raw stone is suitable for cutting the required shape

- Weight and size: the number of carats that meet the design requirements

- Origin: Some gemstones such as Tanzanite and Colombian emerald have clear value distinctions for their origins

In order to ensure traceability, high-end manufacturers will also register gemstones with numbers and provide third-party certification (such as GIA, IGI, etc.) when necessary.

Common gemstone types

Different gemstones have their own symbolic meanings and physical properties, suitable for customized rings with different themes:

- Ruby: symbolizes passion and love, rich colors

- Sapphire: symbolizes loyalty and wisdom, often used in engagement rings

- Emerald: represents hope and rebirth, fresh and unique colors

- Garnet, topaz, tourmaline, amethyst: rich colors, suitable for designer rings

- Diamond: the highest hardness, extremely shining, the first choice for high-end customization

Gemstone cutting and polishing

Cutting rough stones into finished gemstones suitable for ring designs is a technical work that combines art and science. The cutting process includes the following steps:

- Planning and arrangement: maximize the value of the rough stone

- Rough cutting: initially cut out the required shape (round, princess square, marquise, heart shape, etc.)

- Polishing and grinding: form symmetrical and precise facets and perfect proportions

- Sizing fine-tuning: ensure that the cutting size accurately matches the ring setting

The cutting quality directly affects the fire and brilliance of the gemstone, especially in diamond manufacturing. Many professional manufacturers use computer-aided cutting (such as CNC cutting) and laser trimming to improve accuracy.

The fire and luster of a gemstone depend on its cutting process. Mainstream cutting methods include:

- Brilliant Cut: multi-faceted, emphasizing radiance

- Cushion Cut: soft lines, strong retro feel

- Pear, teardrop, princess, oval and other personalized styles

Each gemstone needs to be manually operated by a professional cutter to show the best color and optical effect.

Gemstone processing and calibration

Natural gemstones may have cracks or uneven colors. Manufacturers will use methods such as heating and oiling to optimize the visual performance of gemstones and strictly calibrate the size of gemstones to fit the ring setting design.

After the gemstone is prepared, it will enter the setting stage to perfectly blend the gemstone with the metal.

Gemstone setting: the precise art of holding the gemstone firmly

The cut gemstone still needs to be properly set in the setting to be firmly and elegantly fixed in the ring setting. The setting technology not only determines the safety of the gemstone, but also affects the look and style of the entire ring. An excellent custom ring manufacturer usually chooses the most suitable setting method according to the type, shape and ring design style of the gemstone.

Common Setting Methods

- Prong Setting: The most common form, using 3 to 6 metal claws to grasp the gemstone to maximize the display of the gemstone’s brilliance.

- Bezel Setting: The metal ring wraps the gemstone, which is highly safe and suitable for daily wear or irregular-shaped gemstones.

- Channel Setting: Multiple small gemstones are embedded in metal grooves, often used in row setting design.

- Pavé Setting: Densely inlaying broken diamonds to create an overall shining effect.

- Tension Setting: Fixing the gemstone through metal tension, visually it seems to be suspended in the air.

Setting process

- Adjust the size of the setting: Use professional tools to calibrate the setting to match the gemstone

- Manual embedding and fixing: Technicians use microscopic tools to accurately set the setting to ensure that it is firm and does not crack the gemstone

- Polish the edges and claws: Prevent scratches and improve the overall appearance

- Final inspection and correction: Test whether the gemstone is firm and whether the angle is symmetrical

Setting is a link that is highly dependent on manual experience. A slight error may cause the gemstone to loosen or have appearance defects. Therefore, high-quality rings are usually completed by setting masters with many years of experience.

Quality inspection and refinement: Every detail cannot be compromised

After the metal structure and gemstone setting are completed, the gemstone ring must undergo a series of strict quality inspection processes to ensure that every product leaving the factory is impeccable. This is not only about customer satisfaction, but also reflects the brand’s professional level and sense of responsibility.

Appearance inspection

Whether there are scratches, pores, uneven solder joints, etc. on the surface.

Whether the gemstone is centered, firm, and symmetrical.

Whether the claws are smooth and not scratchy, and whether the polishing is in place.

Whether the metal color is uniform and the integrity of the coating.

Structure and firmness test

Use light vibration and tension instruments to check whether the gems are loose.

Perform tension tests on welding points and chain buckles to ensure load-bearing capacity.

Check whether the ring size is standard and match it with the number.

Multiple manual quality inspections

Experienced QC (quality control) personnel usually conduct 3 to 5 manual quality inspection processes to inspect products from different angles to ensure that there are no omissions.

Finished product cleaning and packaging: Delivering quality to customers

Gem rings that have passed quality inspections need to undergo final cleaning and finishing treatments, and then enter the packaging stage to prepare for formal delivery.

Ultrasonic and steam cleaning

Rings may be attached with metal dust, grease, etc. during the production process, and need to be cleaned by ultrasonic vibration and combined with high-pressure steam spraying to restore their original luster.

Mirror polishing

The last polishing treatment can make the metal surface mirror-smooth and make the gems more shining.

Customized packaging

High-end manufacturers usually configure each ring with:

- Velvet/leather jewelry box

- Quality assurance card/certificate

- Moisture-proof bag, shockproof material

If supplying to brand customers, customized packaging services can also be provided, including brand LOGO silk screen, exclusive tag, QR code label, etc., to enhance the overall market image.

| Start Your Custom Order | Email: info@fulcol.com | Number: +86 13055603907 |

The birth of a gem ring is the crystallization of design, craftsmanship, emotion and time. It starts with a sketch, goes through 3D modeling, proofing, metal casting, gem cutting and inlaying, and layers of quality inspection, and finally turns into a work of art that shines on your fingertips. Behind each process is the creativity of the designer, the delicate craftsmanship of the craftsman, and the manufacturer’s adherence to quality.

For wholesalers who want to enter the field of jewelry customization, understanding this complete process is not only a reference for purchasing decisions, but also the key to establishing long-term cooperation and judging the professional strength of manufacturers. High-quality custom ring manufacturer not only provide exquisite products, but also provide reliable delivery time, stable quality control system, flexible customization capabilities, and brand value that can grow with you.

The next time you admire a fine gemstone ring, think of the journey it has taken – from imagination, through technology, art and emotion, to the stunning gift you hold in your hands.